Your shortcut to metallurgical accounting and process optimisation.

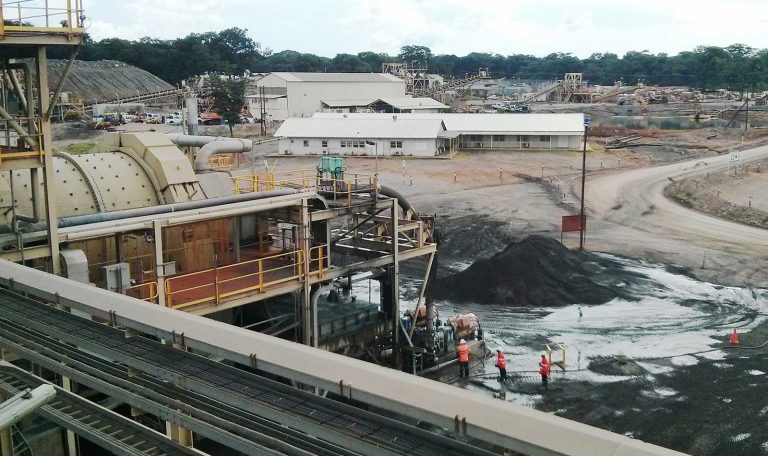

Highly customisable, off-the-shelf mining industry software, relied upon by leading plants around the world.

Metallurgical Systems has invested over 10 years and 400,000 hours of research and development to create the world’s most advanced metallurgical accounting and process optimisation solution in the market.

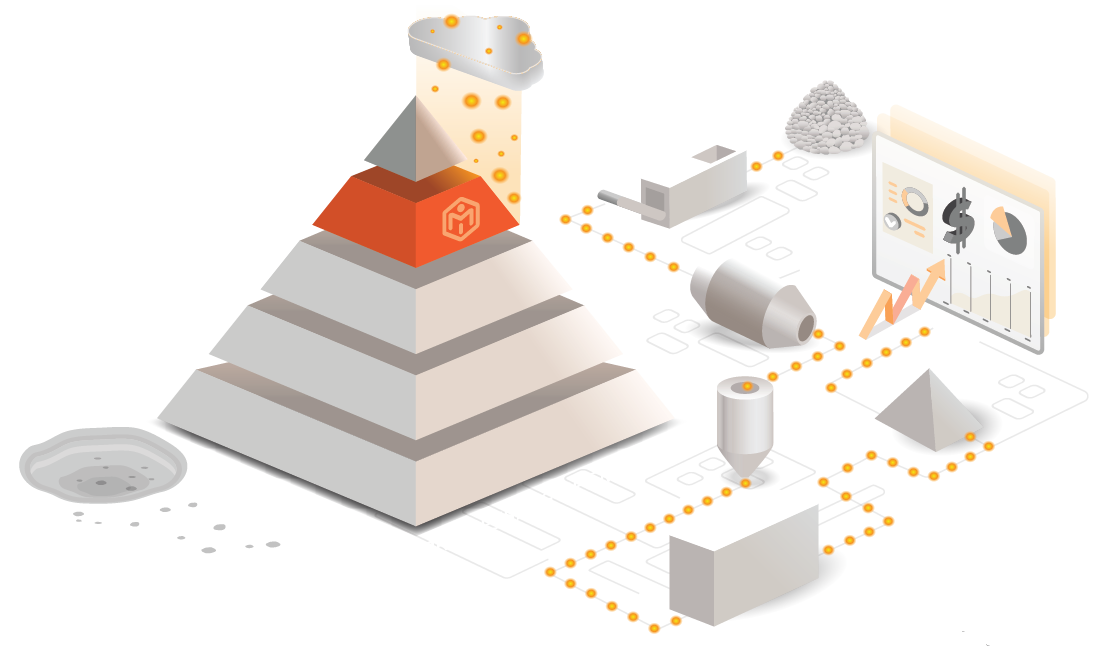

Our mining digital twin solution helps you to streamline your metallurgical accounting and production reporting and get unrivalled insights, providing you with a proven shortcut to digital transformation, compliance, operational excellence, ESG goals and enhanced commercial outcomes.

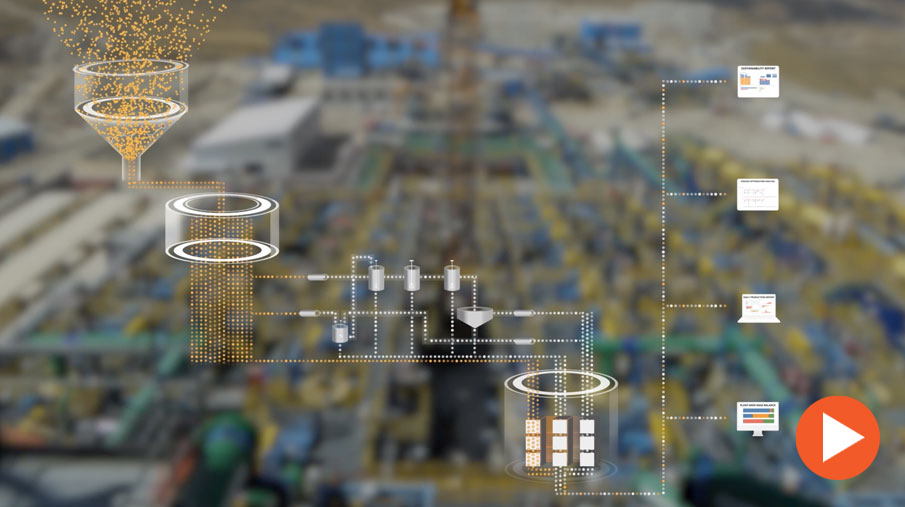

How MI Core® works

ESG Reporting

Learn about the latest policies around soon-to-be mandatory sustainability compliance and reporting requirements for minerals and mining organisations, and how producing auditable financial-grade reports on scope 1, 2 and 3 emissions is possible with accurate data and the right digital tools.

Modern mining technology

Fast-track digital transformation in your minerals processing plant

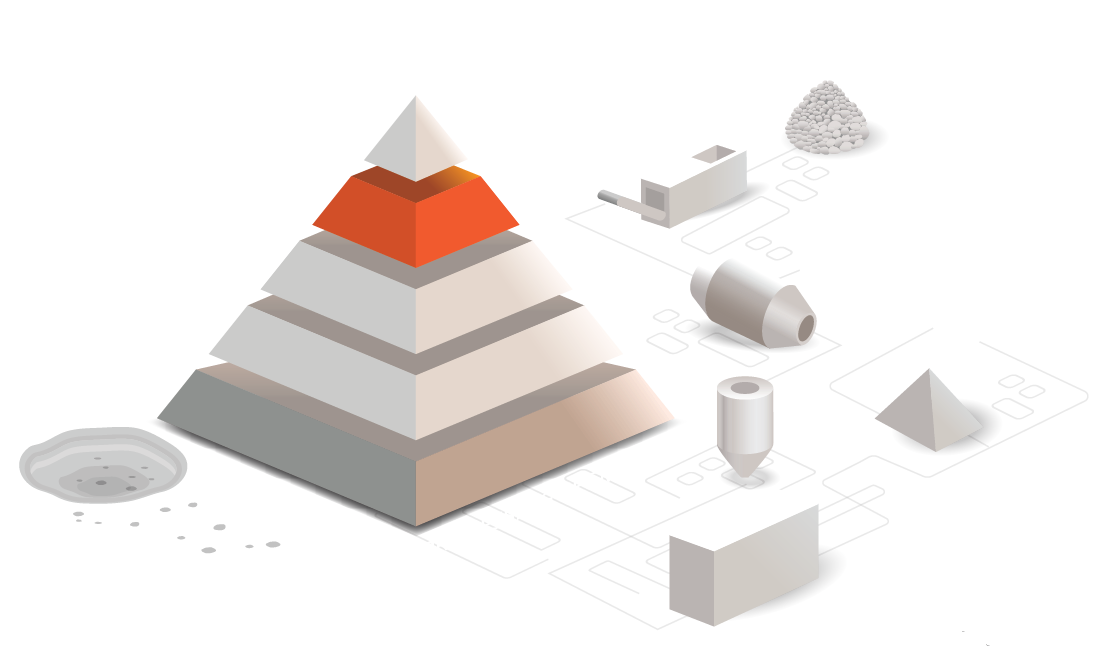

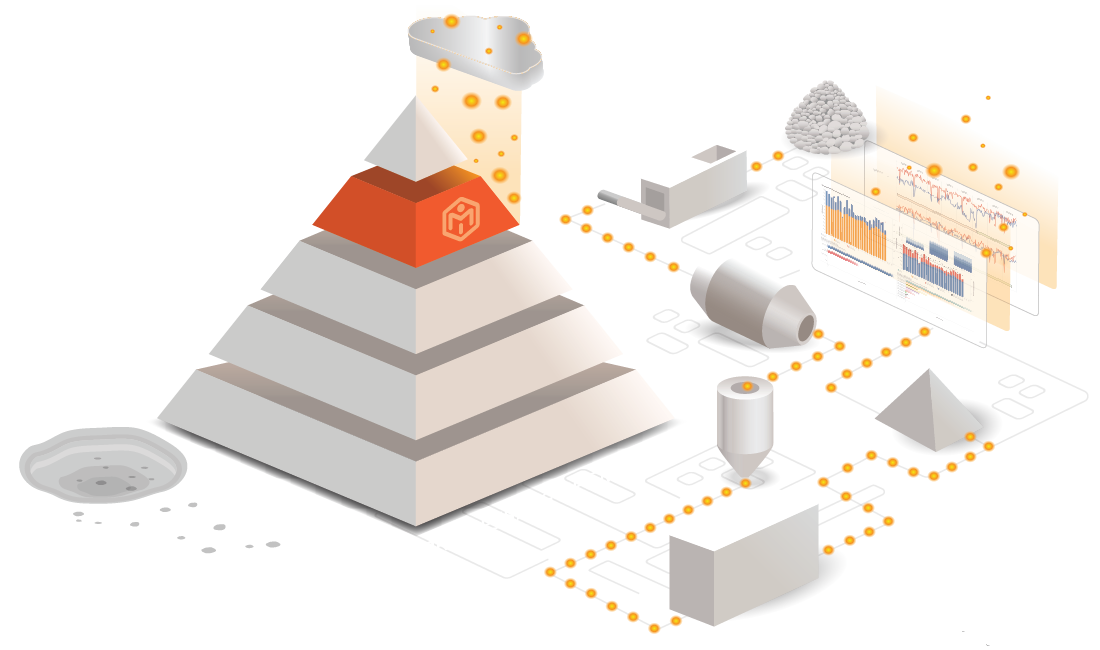

For complete digital transformation across the entire mining value chain, it’s vital that minerals processing plants implement digital solutions for all layers of the automation pyramid. Click through the levels of our mining automation pyramid to see an overview of best-practice automation for a minerals process plant.

Get to know the Metallurgical Intelligence® suite

The only enterprise-wide digital twin, metallurgical accounting and process optimisation solution for minerals processing

Our expertise spans engineering consultancy through to digital process optimisation solutions.

Clients include:

What customers say

Awards

Memberships & partnerships

FAQs

There are two distinct types of digital twin solutions used in mining digital transformation. The first type of mining digital twin is an asset digital twin. This is essentially a digital replica of a physical component of a mine, developed using CAD modelling. This type of digital solution helps stakeholders visualise their facility when remote. For example, it could be 3D modelling for mine planning that includes things like pit designs, haul routes and mine layouts.

The second and far more sophisticated digital twin is referred to as a process digital twin. This is essentially a digital replica of the actual processing of the ore body for a minerals processing plant – from raw material to finished product. This type of digital twin mining software uses dynamic simulation and machine learning, and considers a range of physical properties, such as temperature and pressure. The information from this digital twin can be combined with the specific chemical equations and processes that occur at each step of the refining process to deliver more comprehensive and accurate insights right across the digital mine.

Metallurgical Intelligence ® is a process digital twin.

- Machine learning – that enables data analysis at a scale never seen before.

- Digital twin – with high-performance dynamic simulation to provide stakeholders with an end-to-end, highly sophisticated digital replica of the plant.

- High-performance computing – with the ability to process big data volumes effectively.

- Automated processes – that free employees to focus more on analysis than administrative tasks.

- Data centralisation – and the latest in database technology, so all of the plant’s data can be brought together into a secure, central location for superior analysis.

- Sophisticated reporting and analysis tools.

Yes, Metallurgical Systems is also a mining consultant and metallurgical consultant. We provide consulting services through our consulting arm, Elemental Engineering. We advise on mining processes, process simulation and design, carbon accounting and more.

As the world strives to reach net zero emissions by 2050, demand for critical minerals and battery metals is increasing – led by the shift to renewables technology and green energy. Minerals processing plants need to maximise reco and operating efficiencies. Producing the highest-grade product, and getting the most out of finite resources, means having finely tuned processes and systems in place.

For over 20 years, the team at Elemental Engineering has been providing a range of consulting services to help minerals processing plants optimise their operations. Our experienced team of engineers and metallurgists are highly skilled in the processing of critical minerals and battery metals such as nickel, cobalt, copper, lithium, graphite, aluminium, manganese, rare earths and platinum group metals across all type of processes.