Metallurgical Digital Twin

Optimise operations and performance with a metallurgical digital twin

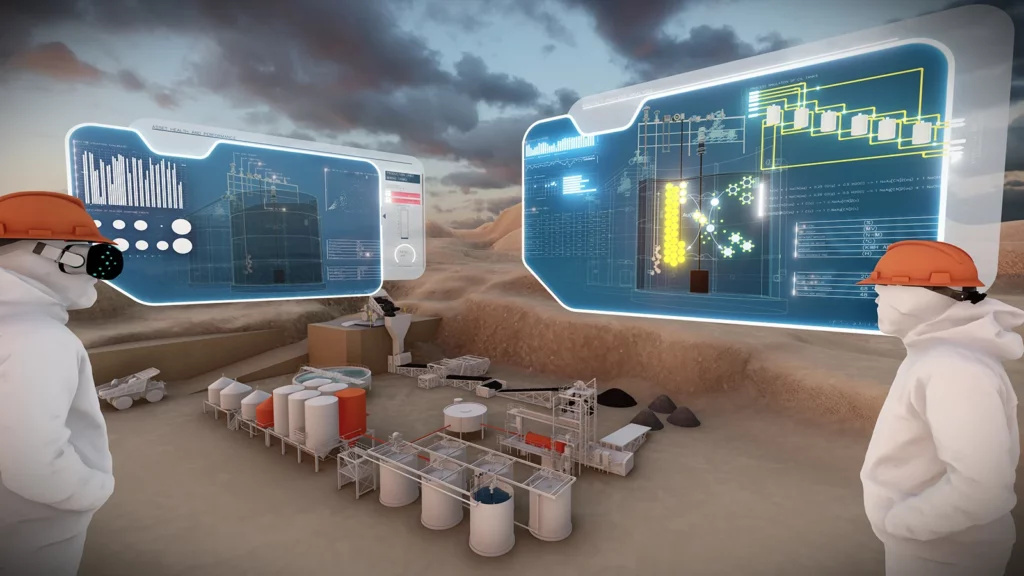

Using a process digital twin, you can create a virtual model of your entire plant to enable more sophisticated decision-making, simulation testing, monitoring and reporting.

Unlock new value from data

Embrace this powerful Industry 4.0 technology to turn plant data into a critical asset.Optimise output to meet demand

With critical minerals in high demand, a digital twin helps extract more from your ore.Solve for sustainability

Run simulations to reduce waste, lower emissions, and achieve transparency with ESG reporting.

70% of C-suite technology executives at large enterprises are exploring and investing in digital twins.1

Replicate your mining plant with a metallurgical digital twin

A metallurgical digital twin is a process digital twin designed specifically for mineral processing plants. The digital replica mirrors the processing of ore from pit to port – enabling data-driven insights, process optimisation, accurate metallurgical accounting and ESG compliance.

Plant-wide data is centralised, validated and contextualised using dynamic simulation to perform a mass and energy balance at every step of the process.

The dynamic simulation considers a range of physical properties, such as temperature, pressure and time lag dependency; as well as the specific chemical equations and processes that occur at each step of the refining process. It also uses machine learning, multidimensional and relational database structures, advanced data analytics and visualisations to run simulations and test scenarios that drive process optimisation.

But not all digital twins are created equal, particularly in the mining and industrial sectors.

Achieve plant-wide optimisation with Metallurgical Intelligence

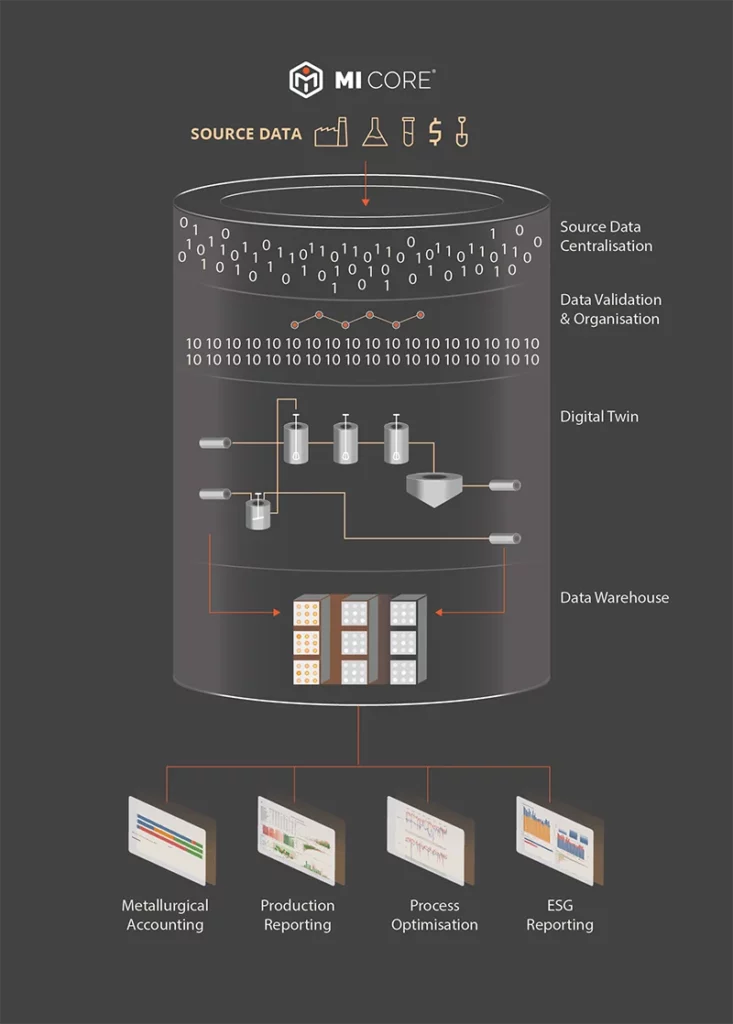

MI Core®, part of the Metallurgical Intelligence suite of solutions, is an award-winning, industry-leading process digital twin solution for the minerals and mining sector. The platform captures, centralises, consolidates and validates massive volumes of disparate source data fast – so you can start running digital twin calculations at speed.

Plus, with MI Core®, it’s easy to keep pace with the latest finance-grade sustainability reporting requirements for direct and indirect emissions (scopes 1,2 and 3), energy and water consumption, and other key sustainability metrics like waste, recycling and air quality.

Used across the globe, MI Core® is available in four languages (English, French, Spanish and Russian).

Why MI Core® for your digital twin?

- Near real-time insights

MI Core®uses parallel processing to eliminate lag time between source data, digital twin calculations and data warehouse applications.

-

Dynamic simulations

With near real-time, granular insights across your plant, you can run dynamic simulations to support scenario testing, forecasting and decision making.

-

Plant-wide calculations

Using MI Core®, you can perform a plant-wide mass and energy balance, hourly, at every step of the process.

-

Product batch data

Track and get full transparency across product batches at every step of the process – at the site, between sites, and from pit to port – to optimise recovery and reduce waste.

-

Metallurgical accounting

Perform site-specific metallurgical accounting, and use the insights to optimise processes and productivity.

-

Sustainability reporting

Accurately track and report on key sustainability metrics, use data to find ways to reduce emissions and waste, and more easily achieve regulatory compliance.

-

Process automation

Drive efficiencies by automating manual tasks associated with monitoring a plant’s performance, comparing data, and producing reports.

Our digital twin delivers proven results

Recovered

2.1 tonnes of gold lost to tailings

Saved

in lost revenue + a plant shutdown

Detected

of underreported product losses per year

Identified

in product lost to tailings per month

What customers say

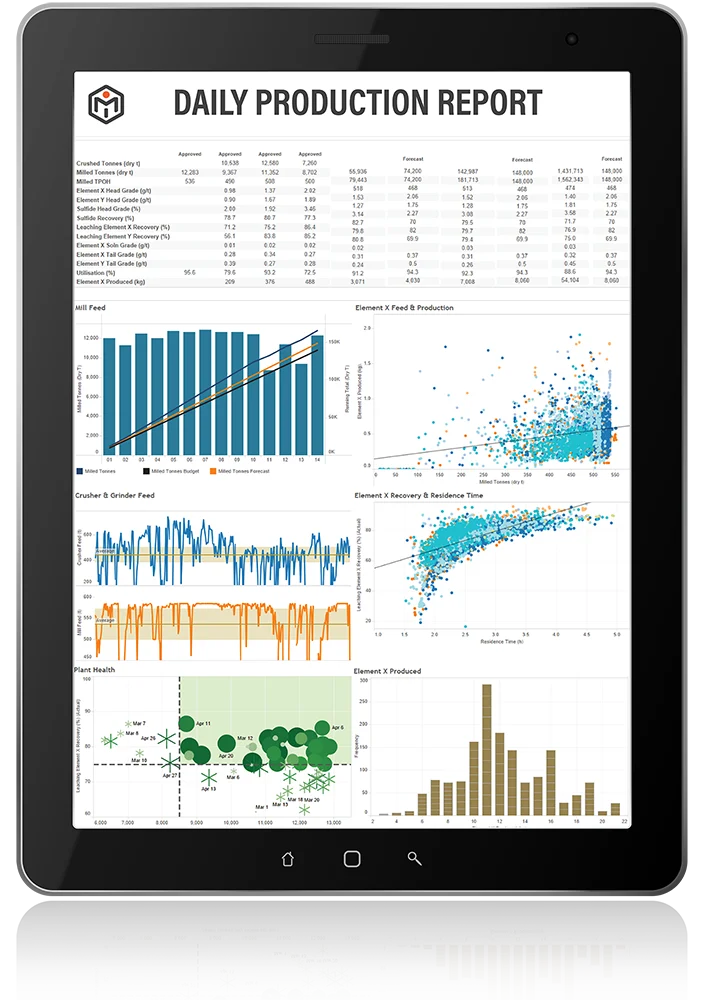

Rich reports and dashboards provide full visibility

- Metallurgical accounting

- Process optimisation

- Production reporting

- Sustainability reporting