Optimise your plant’s processes

A smart tool that leverages the power of metallurgical machine learning to review your plant’s performance and provide answers to critical operational questions.

MI Process Optimiser® provides a robust shortcut to continuous metallurgical process optimisation. Using metallurgical processing statistical analysis, it identifies patterns in your data to quantify lost opportunities and develop strategies for adapting to challenging operating conditions. Part of the MI Core® suite of software, MI Process Optimiser® can help you make smarter decisions and achieve maximum profitability for your plant.

How it works

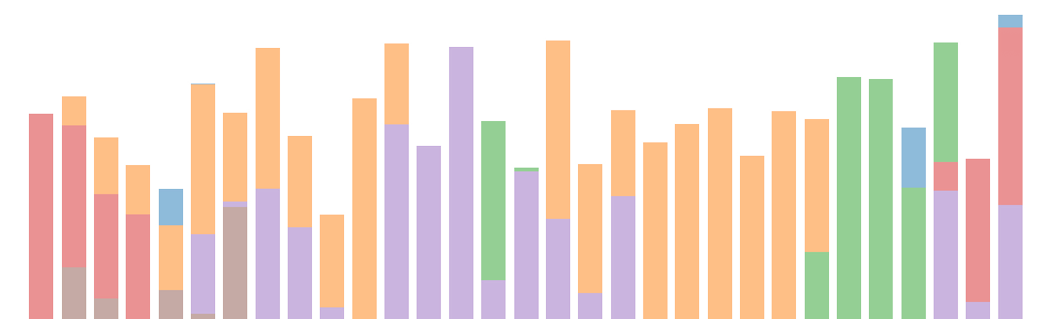

MI Process Optimiser® captures data from millions of points across your plant to help you find the optimum processing conditions according to a range of different parameters. These optimised conditions can then be compared with real plant data, to help you determine how your plant is tracking, and enabling you to adjust your processes to ensure maximum recovery and production. For instance, you can examine the effect of different variables on a process (e.g. feed rate, temperature or particle size) to get a desired result, or investigate the bias between your plant’s measured values and calculated values. If a consistent bias is uncovered, you can then analyse the results to investigate issues with the instrument or lab assay.

Key Features

Continuous learning and improvement

Leverages machine learning to continually learn about how your plant operates. The more data and runs it analyses, the more sophisticated it becomes in uncovering patterns and insights that enable metallurgical process optimisation.

Accurate, reliable insights

Uses the big data captured and calculated by MI Core® to perform the most detailed and accurate insights. Also caters for time lag dependency, performs non-linear calculations and caters for multiple variables.

Fully integrated

Results from MI Process Optimiser® can be combined with MI Core® to help you develop smart, realistic plant operating forecasts.

Benchmarks your results

Compare optimal results with actual results, so you can identify how your performance can be improved. Get specific insights based on your outputs – such as the optimal conditions for treating different ore types.

Instant notifications

Captures data from a wide array of plant data sources and provides instant notifications so you can make fast decisions based on what is happening in real time. Leverage this data to identify any root-causes of problems or patterns.

Transparency

Get complete transparency regarding your equipment performance, as well as insights regarding the KPIs of individual pieces of equipment over time.

The MI Process Optimiser® difference

- Custom data validation tools ensures clean machine learning data

- Objective analysis of past performance

- Able to handle non-linear problems

- Big data calculated by MI Core® digital twin for superior results generated by MI Process Optimiser®

- Combined global and local view

- Time-lag dependency is calculated

- Can be scoped and deployed 100% remotely

- Expert training and support