Process Simulation Specialists

Accelerate outcomes with world-leading metallurgical expertise

Global experts in process design, simulation and metallurgical consulting for all minerals processes including critical minerals, battery metals and ESG reporting and analysis.

Growing demand for critical minerals and battery metals

As demand increases – led by the shift to renewables technology and green energy – minerals-processing plants need to maximise recovery and operating efficiencies. Producing the highest-grade product and getting the most out of finite resources means having very finely tuned processes and systems in place.

As peak mining bodies and investors put more emphasis on ESG, efficient processes, combined with emissions and water use modelling are vital to ensure mining sites can track, manage and report on their ESG goals.

Achieving greater efficiencies

The process design and simulation team at Metallurgical Systems is called Elemental Engineering. First established in 2006 as a specialist process simulation, metallurgy and design engineering consultancy, this highly experienced team provides a range of services to help minerals-processing plants optimise their operations.

Our team are experts in all types of processing and analysis for minerals including developing and refining processes that enable cost-effective extraction of critical minerals and battery metals such as uranium, nickel, cobalt, copper, lithium, graphite, aluminium, manganese, rare earths and platinum group metals, gold and silver.

In 2010, the Elemental Engineering team expanded into developing software and technology for the mining and minerals industry and Metallurgical Systems was established.

What we do

- Pressure metallurgy

- Solvent extraction/ Ion exchange

- Solid/liquid separation

- Leaching: atmospheric, heap, in-place, bio and pressure

- Solvent extraction/ Ion exchange

- Precipitation; including carbonate, sulphide and mixed hydroxide

- Gravity processing

- Uranium oxide production

- Solid/liquid separation

- Electrowinning and electrorefining

- Hydrogen reduction

- Digital transformation and automation consulting

Key Specialist Services

Process simulation

Development of steady- state and dynamic process simulation for complex metallurgical processes to validate process chemistry, compare process options, and conduct surge and availability analyses, and reliability reviews.

Process design and optimisation

Optimisation recommendations for ore characterisation processes; concept process design and development; process optimisation and validation; process evaluation and detailed engineering design support.

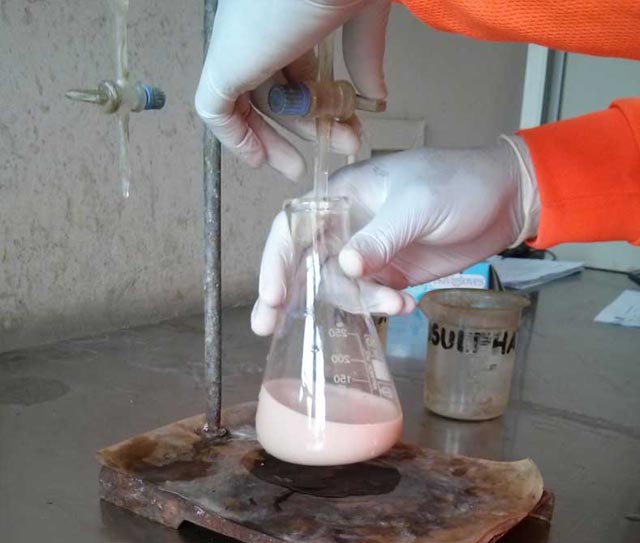

Testwork management

Provision of program definition, supervision and interpretation for metallurgical testwork management.

Scoping and pre-feasibility studies

Preparation of scoping and feasibility studies and detailed option analyses through our process modelling expertise. We also provide ongoing support into the detailed engineering phase of the project for smooth project delivery.

Environmental and sustainability reporting

Assistance with capturing, analysing and reporting on your plant’s greenhouse gas emissions, water and power consumption – in accordance with the regulations in your jurisdiction. Set budgets, targets and forecast ways to reduce emissions.Battery metals and critical minerals

Expert advice on how best to optimise production of battery metals – which require technology to remove the last few thousand parts per million of impurities to ensure they are commercially viable and competitive.Elemental Engineering differences at a glance

- Steady-state and dynamic simulation

- Critical minerals and battery metals-processing experts

- Process design and optimisation

- Scoping and pre-feasibility studies

- Testwork management

- Flowsheet scenario analysis

- Carbon accounting – scopes 1, 2 & 3

- Over 20 years of global project consulting