Metallurgical Process Optimisation

Mine your big data to optimise plant performance

A process optimisation solution helps you answer critical questions about your metallurgical plant’s performance and, ultimately, boosts your bottom line.

Gaining a complete picture of your plant’s performance can be incredibly challenging. Across all your assets, thousands of sensors are continually taking measurements, monitoring for wear and tear, evaluating inputs and outputs, and more. All this data can be invaluable in helping plant operators identify areas for improvement, but it’s worth nothing if it’s locked in siloes or inflexible systems.

There is a huge opportunity in metallurgical processing plants to unlock the true value of data. If decision-makers can gain a clear picture of plant performance, they can more accurately control for productivity, safety, and profit margins — while also helping reduce waste and meet sustainability targets. To deliver these critical insights, industry leaders are embracing the very latest machine learning technologies and process optimisation solutions.

Optimise output and plant performance

Apply ML to your plant data to help plant operators and engineers make more strategic decisions.True intelligence in your control room

Predict and optimise plant operations by testing and adjusting variables in near real-time.Leverage a digital twin to boost predictive capabilities

Use the most advanced technologies to identify patterns in your data.| Traditional ways of interpreting plant data | With MI Process Optimiser® |

|---|---|

| Subjective – relies on people’s experience | Objective – automatically learns patterns from historical data held in MI Core® |

| Linear – difficult to identify relationships between data components | Non-linear – enables multi-dimensional models |

| Static – rough estimation only for time dependencies | Dynamic – conditional probability estimation of time dependencies |

| Local – looks at each stage of processing independently from one another | Global – considers each step of the process and its relationship to one another, as well as the context of the entire process as a whole |

The global market size of AI in mining grew at a CAGR of 10.0%, from $634.9 million in 2019 to $767.9 million in 2021.

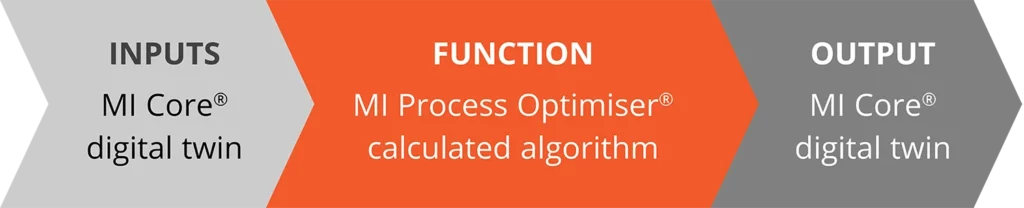

Optimise metallurgical plant performance with MI Process Optimiser®

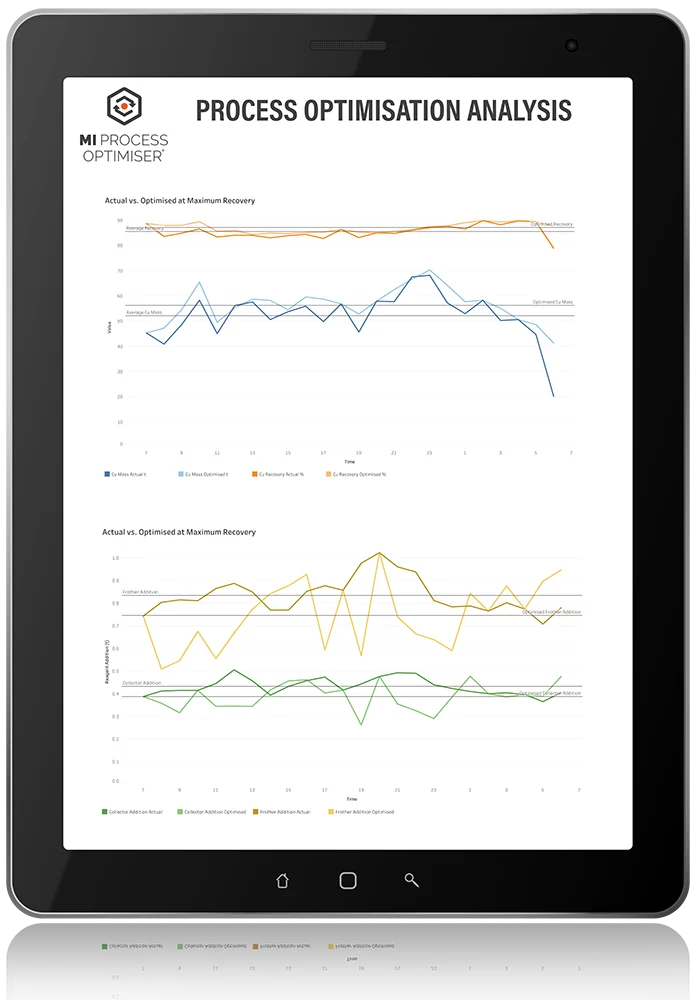

MI Process Optimiser® pairs the power of machine learning with metallurgical processing statistical analysis to continuously review your plant’s performance — ultimately helping you make smarter decisions to minimise potential losses and maximise profits.

By capturing and centralising data from millions of points across your plant, MI Process Optimiser® can identify powerful patterns in your data and help you land on optimum processing conditions according to a range of different parameters. Using a digital twin, you can compare these conditions with real plant data, investigate issues, and make adjustments in near real-time to optimise production.

Why MI Process Optimiser® for optimising plant performance?

- Continuous learning and improvement

With machine learning at its core, MI Process Optimiser® is continually learning how your plant operates. The more data it analyses, the better it gets in uncovering patterns and insights specific to your plant. - Accurate insights from quality data

MI Process Optimiser® analyses validated, clean and accurate data from MI Core® — a custom-built digital twin that completes 720 iterations of a full plant wide mass balance a day. - Fully integrated

Results from MI Process Optimiser® and MI Core® can also be integrated with mine plans, cost estimates and other information for a truly holistic view of future performance. - Benchmarks your results

Compare optimal results with actual plant performance to spot ways to improve. MI Process Optimiser® also delivers specific insights based on your outputs — such as optimal conditions for treating different ore types. - Caters for time lags

No process within a plant is static. MI Process Optimiser® takes time lag dependencies into account — such as when an input (feed) cannot be correlated with an output (tails) at the same time, on the same day. - Fully customised to your plant

MI Process Optimiser® has been adapted for every type of minerals processing technology, including concentrators, hydrometallurgy plants, smelters and refineries. Even the most detailed process parameters can be captured and reported. - Logical, trusted results

Know that you’ll never receive illogical results from MI Process Optimiser®. It determines the multi-dimensional constraints of controllable variables to ensure reported results are in line with mass conservation limits. - Non-linear calculations

Given the processes within a typical plant have many variables, MI Process Optimiser® uses complex multi-dimensional modelling to cater for this non-linear nature.

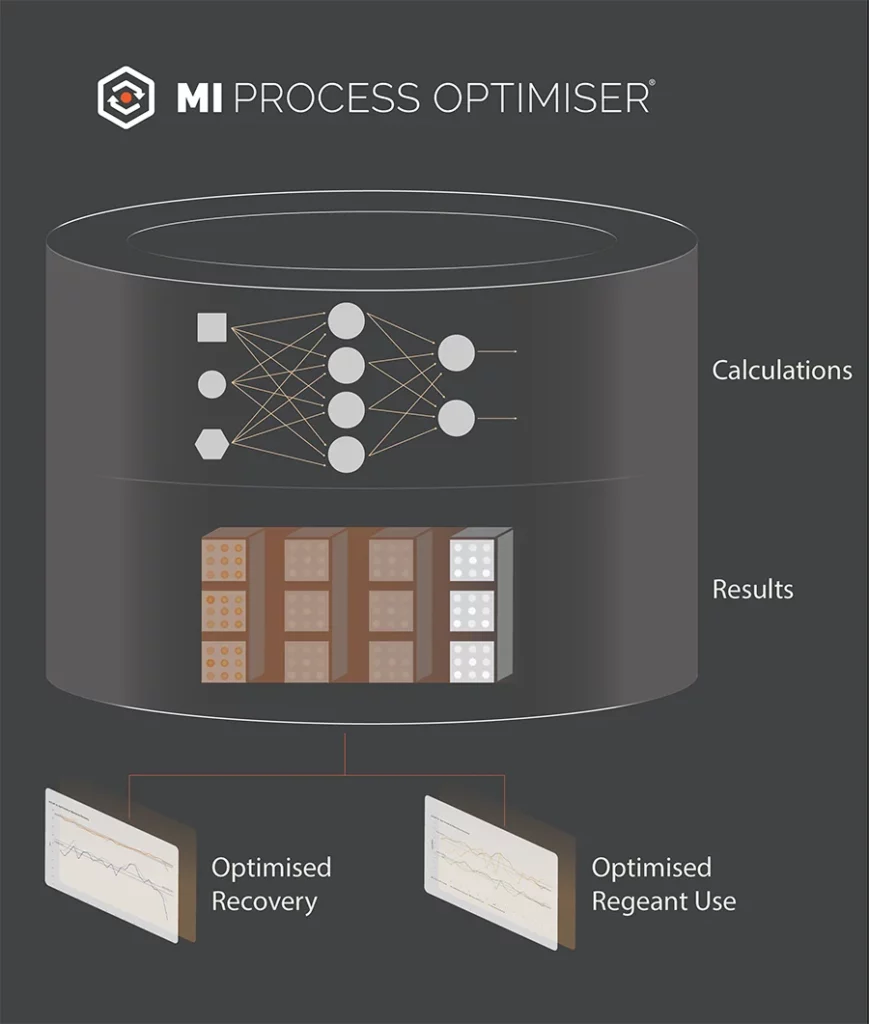

Millions of data inputs deliver optimum results

MI Process Optimiser® uses millions of data inputs and outputs generated by the digital twin solver from MI Core® to calculate optimum values for controllable variables — ultimately delivering extremely detailed and accurate results.

Our process optimisation solution delivers proven results

MI Process Optimiser® is proven to deliver actual improvements in mineral processing plant operation:increased recovery

of potential improvements pa