Mining Asset Utilisation

Optimise your mining plant performance

Use a mining asset utilisation solution to predict asset maintenance, reduce downtime, improve equipment effectiveness and more.

As the mining industry grapples with declining grades and scarce ore bodies, optimising production efficiency and recovery is now a top priority.

To get the most from plant performance, industry leaders are turning away from spreadsheets and manual logsheets, which compartmentalise and limit the availability of critical production data. Instead, they are embracing the many benefits of digital mining asset utilisation solutions.

By putting the right data in the hands of decision-makers at the right time, a mining asset utilisation solution helps plant operators realise dual goals of optimising plant performance and reducing maintenance costs.

Use asset data to your advantage

By improving overall plant performance, you can make the mineral processing function more profitable.Minimise downtime, optimise output

Shift from reactive to proactive maintenance to operate your plant more efficiently.Achieve plant-wide excellence

From safety to cost optimisation, use powerful insights and real-time reports to drive more effective decision-making.

75% of global mining leaders now view technology disruption as an opportunity rather than a threat.1

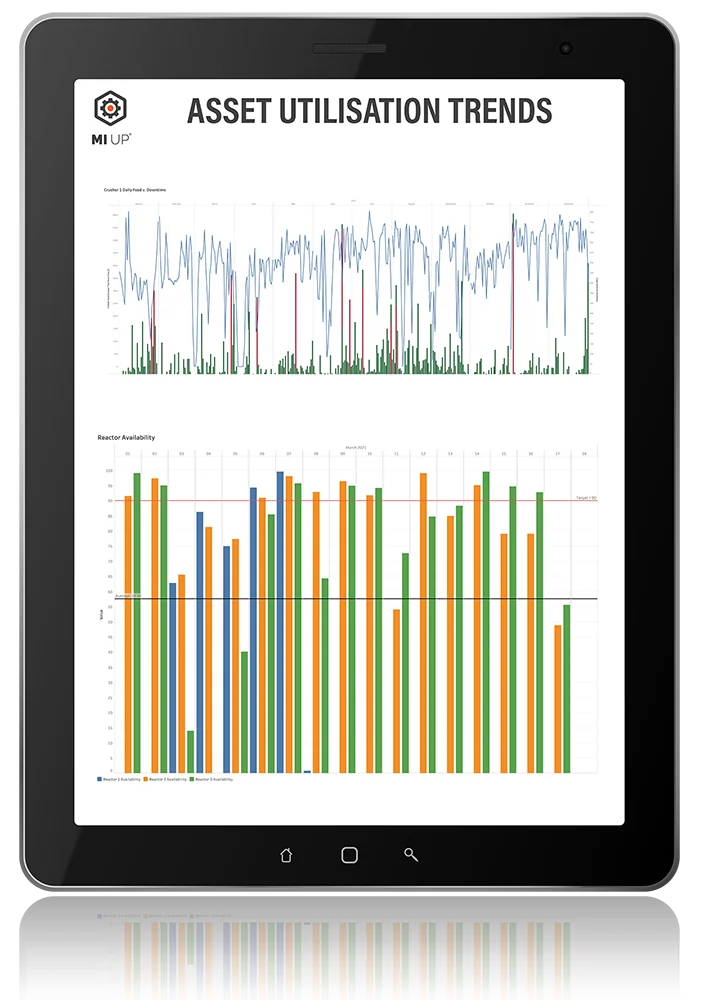

Continually monitor metallurgical plant performance with MI UP®

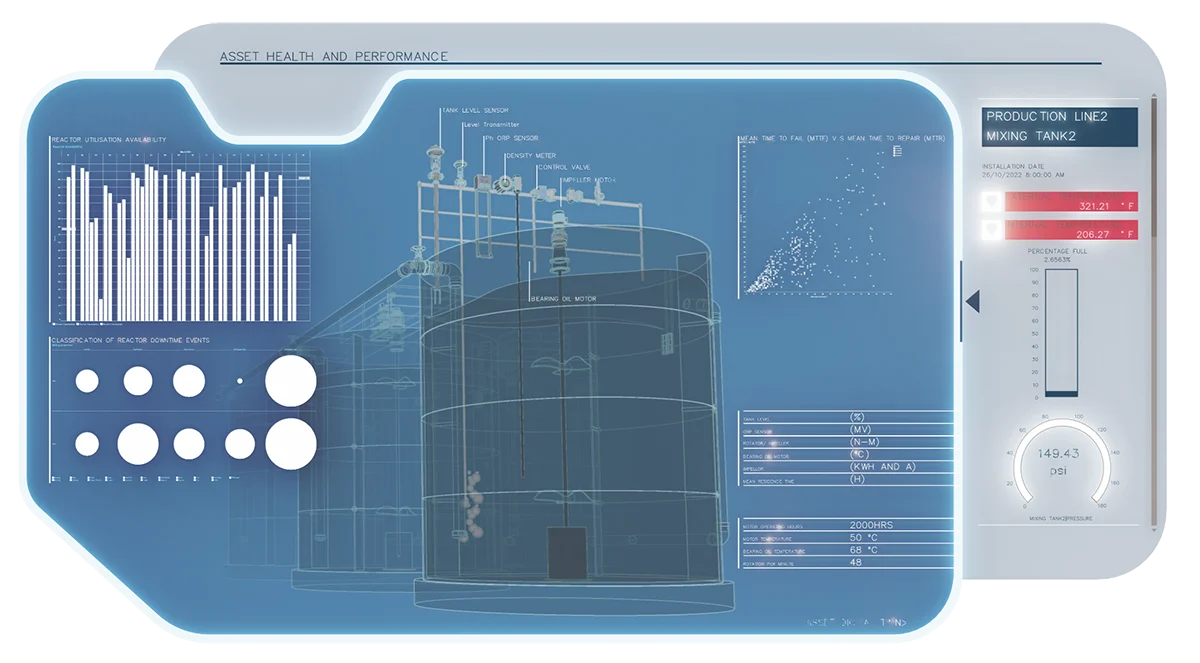

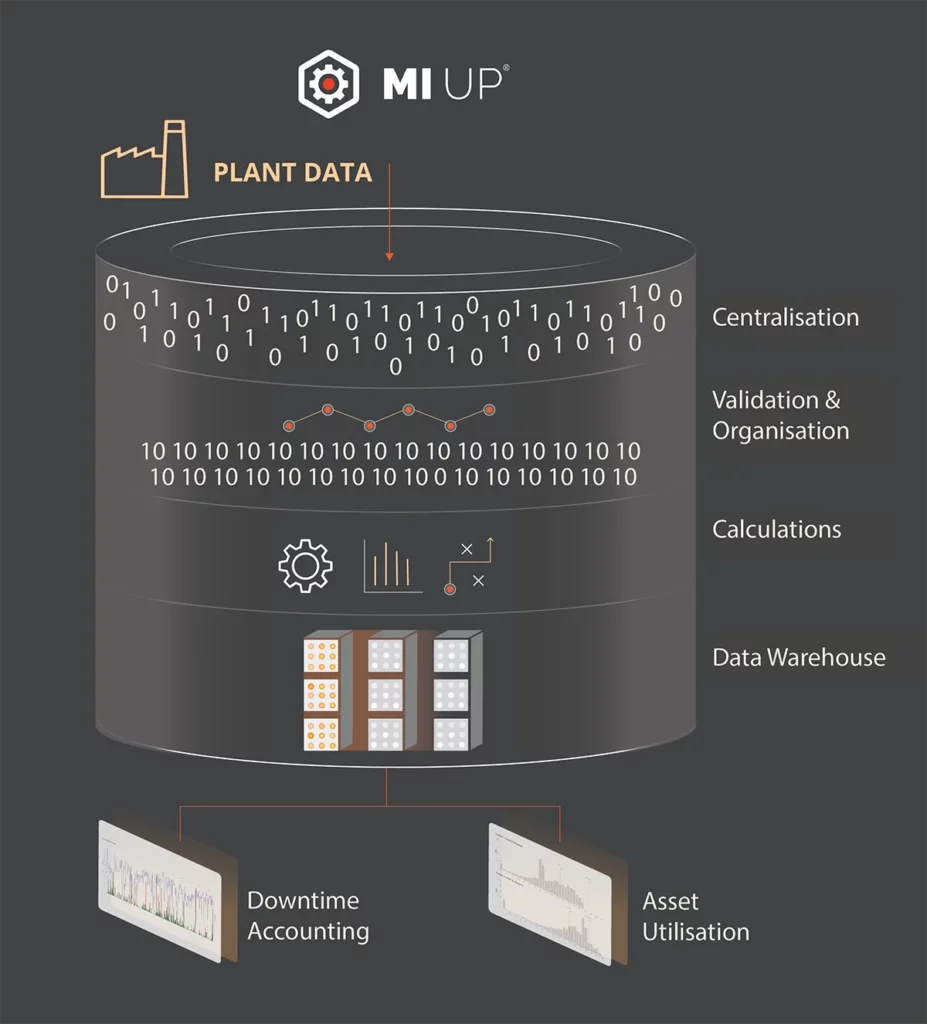

MI UP® is a mining asset utilisation solution that continually captures plant equipment delay and downtime events, providing a data-driven indication of root causes and likely future production losses.

The rich insights derived from the solution facilitate strategic decision-making and help you pave a path to profitability and growth. By replacing manual monitoring and reporting with a digitised, automated system, you can:

- Shift from reactive to proactive equipment maintenance

- Identify and resolve bottlenecks in availability

- Avoid equipment downtime

- Accurately determine the causes of any plant equipment issues

- Save costs and avoid waste

- Justify capital expenditure requests

- Extend equipment life

- Increase production rates

- Operate more efficiently

- Optimise energy usage

- Improve safety and compliance

MI UP® can be implemented as a standalone solution or integrated with other technologies to achieve an even greater level of insight and control.

Why stop at asset optimisation?

Pair your mining asset utilisation solution with a process digital twin to get much deeper context and plant-wide insights.

For example, you can pair MI UP® with Metallurgical Intelligence’s process digital twin, MI Core®. Together, the two solutions give you more visibility across your plant:

- MI UP® delivers rich equipment insights like predictive analysis, downtime accounting, equipment effectiveness and utilisation

- MI Core® delivers process chemistry and thermodynamics insights, showing you what is happening inside the assets and equipment

Why MI UP® for mining asset utilisation?

- Customised to your plant

MI UP® is modelled around your specific plant equipment, processes and flowsheet — and captures data from a wide array of plant data sources — to deliver targeted insights that add true value. - Comprehensive detail

Quantitative and qualitative performance and availability metrics are dynamically measured in as many pieces of plant equipment as possible. - Fast, granular reporting and analysis

Drag and drop capabilities make it easy to build advanced data visualisations and dashboards. Processing data is dynamically captured from plant sources every second, reported hourly. - Instant notifications

Maintenance, reliability and production teams get instant notifications, enabling faster decision-making based on what is happening in real time. - Predictive alerts

Using predictive analytics, the tool delivers accurate and meaningful alerts about potential asset issues so operators can rectify them before a failure occurs. - Redundant data capture

If there is a loss of communication with plant data sources, you can re-process that data at a later time when the data source is restored. - Powerful machine learning

By automating classifications based on plant conditions, operators need only provide minimal input — while you get much deeper and richer insights. - Flexible and scalable

MI UP® connects with your plant historian(s) to extract real-time instrument data, prompting an operator for downtime causes or automatically populates these based on defined production situations.

Trusted data you can rely on

Once MI UP® has been implemented, captured plant data is subjected to our custom data validation tool. This identifies and highlights any unusual or biased data, and uses machine learning to ensure data is validated, cleansed and cross-checked at several points of the process.

Data is stored in a high-performance, structured database to provide fast, easy access to pre-aggregated and pre-organised information.

Our asset utilisation solution delivers proven results

MI UP® has been shown to deliver actual improvements in mineral processing plant operations of up to:

- 20% increased throughput in material flow management

- 25% reduction in unplanned downtime

- 20% increase in equipment availability

- 15-40% reduction in reactive maintenance