Paladin Energy Powers Towards A Low-Carbon Future With Its Rebooted Uranium Mine

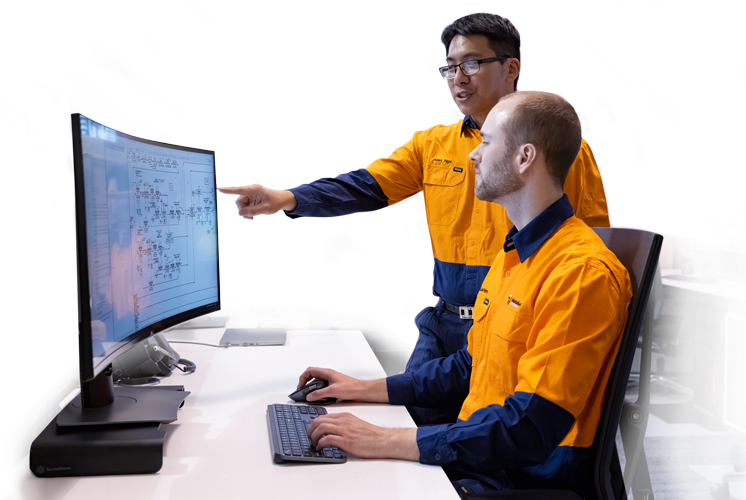

By embracing innovative data-driven tools, Paladin is delivering a reliable uranium supply critical for the world’s transition to a low-carbon, sustainable future.

Metallurgical Systems has specialised in mining business process engineering for over a decade. Our market-leading suite of metallurgical accounting and process optimisation software has uncovered millions of dollars in savings for some of the world’s largest processing operations – providing a unique and effective shortcut to digital transformation, compliance, efficiency, sustainability and profitability. Take a look at these resourcing and mining case studies to learn how.

By embracing innovative data-driven tools, Paladin is delivering a reliable uranium supply critical for the world’s transition to a low-carbon, sustainable future.

Implemented the tools required to cut emissions, by enabling far more accurate, efficient and reliable greenhouse gas accounting and reporting.

Identified gaps between calculated and actual production values that were significantly impacting the plant’s profitability.

Rectified issues after the facility overstated financial performance by over US$41.9m.

Identified cost savings of US$26m per year on reagents alone.

Did away with a complex network of Excel spreadsheets and dramatically improved visibility.

Identified US$21m per year in lost acid production from underreported scope 1 measurement of greenhouse gas emissions.

Unlocked process improvements that continue to deliver ~US$25 million in savings per year.

Identified opportunities to drastically cut its emissions, improve compliance and generate savings of up to US$120,000 per day.

Download case study eBook: