Mining process optimisation using a digital twin

Award-winning, market-leading digital twin technology deployed in mining plants all over the world.

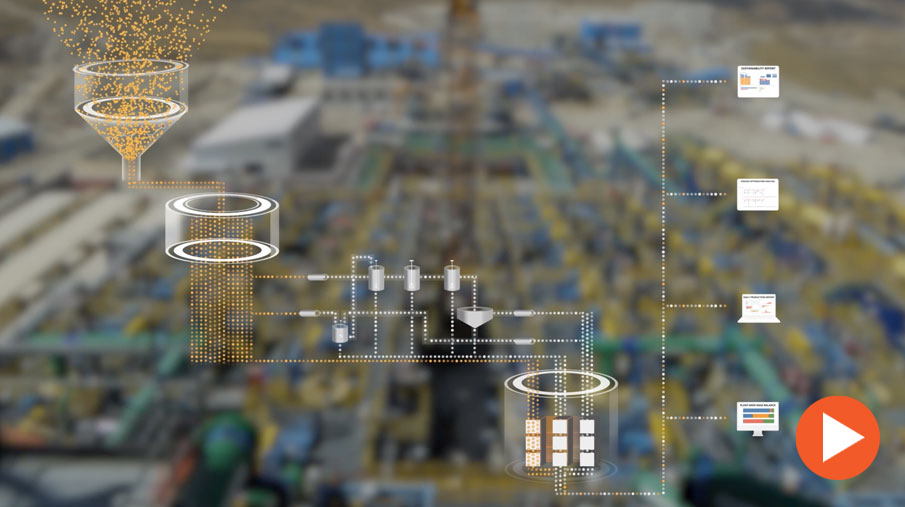

MI Core® is a highly effective shortcut to data-led metallurgical accounting, production reporting and mineral processing plant optimisation. It functions as a digital twin of your mining plant, enabling deep and rapid analysis, ongoing monitoring, and seamless metallurgical production reporting. Via a single, easy-to-use dashboard, you get all of the vital information you need to make smarter decisions, improve profitability, uncover anomalies, identify efficiencies, exceed compliance objectives (AMIRA P754) and eliminate risk.

MI Core® also has an essential emissions reporting function, and can help you capture, analyse and report on your plant’s greenhouse gas emissions and power consumption – in accordance with the regulations in your jurisdiction. Reports are fast, automated, seamless and available hourly.

How it works

MI Core® is the foundation of the Metallurgical Intelligence® suite of software. It rapidly centralises and validates unlimited sources of data from right across your plant to provide you with ultimate clarity and a single source of truth. Using digital twin technology, it creates a comparable set of calculated data for context, and it applies the most advanced analysis and data visualisation tools to get critical information into the hands of those who need it, fast.

Deeper insights, faster

Key Features

Mining Digital Twin

While other solutions use traditional statistical calculations, MI Core® connects directly to source data, and uses dynamic simulation. The digital twin model completes 720 iterations of a full plant wide mass balance every 24 hours and monitors inventory changes over time.

Learns and Adapts

Leverages machine learning to analyse huge volumes of data and provide intelligent, automated insights that can help mine operators make better, smarter decisions.

Fully Customised

Customised to specifically match the unique requirements, processes, equipment and chemistry of the plant at which it is being installed.

Flexible and Scalable

Has been adapted for every type of minerals processing technology, including concentrators, hydrometallurgy plants, smelters and refineries.

Detailed Greenhouse Gas Emissions Reporting

Helps you capture, analyse and report on greenhouse gas emissions, water and power consumption, quickly and easily, in accordance with relevant regulations.Integrated, Accurate and Transparent Data

Is completely automated and offers a single, validated and organised source of truth for all plant data.

The MI Core® difference

- Digital twin

- Site specific chemistry and process dynamics

- Single, centralised source of all site information

- Automated data capture and calculation

- Full transparency back to source data

- Completes a full plant wide mass balance, 720 interactions a day

- Completes complex queries within seconds

- Expert training and support

- Greenhouse gas emission reporting – Scope 1, 2 & 3

- Can be scoped and deployed 100% remotely