Predict future plant performance using data from the past

As a mineral processing professional, you deal with all kinds of “what if” questions on a daily basis. But what if there was a way to answer your questions confidently, based on actual data?

How it works

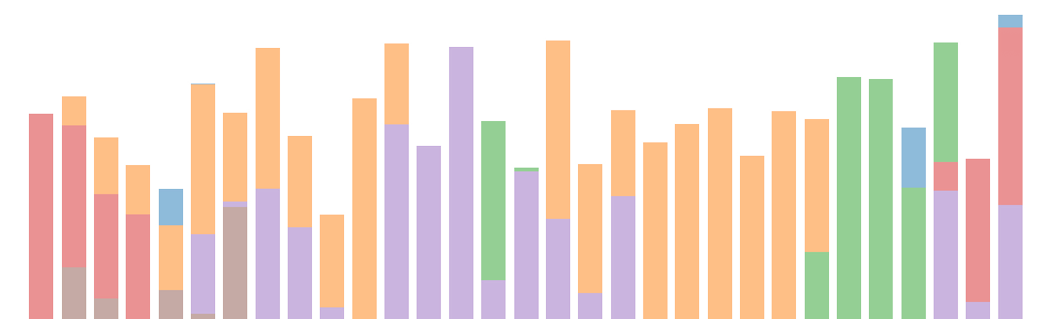

Using a steady-state plant simulation model, MI Scenario® enables you to use data from your digital twin, sourced from across your plant, in order to determine likely future processing outcomes. Thanks to powerful metallurgical processing scenario testing, you can adjust input figures to determine how specific adjustments in variables like feed grades or throughput will affect final product and plant recovery. In addition, by modifying your plant’s historical data or making changes to your plant flowsheet, you can create and compare scenarios using cutting edge reporting and data analysis tools. The results from these simulations automatically flow into MI Core® to help you manage metallurgical production budgeting and forecasting, set targets and compare theoretical results to actual plant performance.

Key Features

Predicts future performance

MI Scenario® uses steady-state simulation technology to predict the future for your plant by combining data from the past with known or expected upcoming changes in processing conditions. With an accurate production forecast, you can make much more precise and informed decisions.Unlimited scenarios

There is no limit to the number of metallurgical production testing scenarios you can run with MI Scenario®. Investigate process optimisation, plan budgets and forecast with unprecedented confidence, conduct stress tests or even trial plant configuration changes.Fully integrated

Uses accurate data captured and validated from within MI Core® as its primary input. Mineral processing organisations who have made the digital transformation also transfer results from MI Scenario® back to MI Core® to use as budget or forecast data.Deep insight

Steady state simulation removes time as a dimension/ variable, which means you can produce more detail from changing other variables such as volume, concentration or temperature.Fully customised

Use MI Scenario® in a way that’s relevant for your particular plant. Simply select a snapshot of historical data as the basis for a scenario, then generate any number of variations as separate cases. You can even customise the plant model to trial different flowsheets and new equipment.Flexible and scalable

Has been adapted for every type of minerals processing technology, including concentrators, hydrometallurgy plants, smelters and refineries.The MI Scenario® Difference

- Generate any number of “what if” scenarios

- Adapted for every type of minerals processing technology

- Integrated into MI Core® using real plant data

- Say goodbye to old manual spreadsheets for budgeting process

- Can be scoped and deployed 100% remotely

- User can change the plant model to trial different

flowsheets and model input values