Maximise the effectiveness and life of your plant equipment

Optimise your metallurgical plant performance by knowing exactly how each piece of equipment and associated process is performing at every step.

When it comes to optimising your plant’s equipment using data, MI UP® offers a highly effective shortcut. This powerful asset utilisation software captures and stores equipment performance information from across your plant, and provides you with real-time delay accounting and downtime reports so you can make faster more accurate decisions.

With MI UP®, you can operate your plant more efficiently, avoid unnecessary equipment downtime, prolong the life of your equipment, increase production rates, and even optimise your energy use. It can either be implemented as a stand-alone solution, or integrated with other technology – like MI Core® and/or ERP Systems, to provide you with an even greater level of insight and control.

How it works

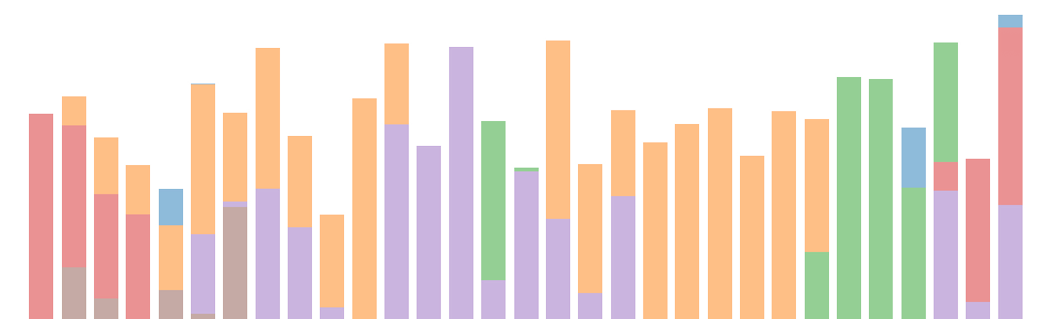

MI UP® offers a range of vital insights that can lead to effective decision making and help you track production asset utilisation, availability and efficiency at all levels of the plant – right down to individual equipment items. MI UP® captures quantitative downtime and efficiency metrics directly from plant instrumentation, with an intuitive ability to capture and track qualitative causes alongside these. Using machine learning, this data can then be automatically categorised as planned or unplanned. The root causes of downtime can be identified and actions required to remedy them can be implemented. Plus, you can easily understand optimal and sustained operating conditions and exactly how your equipment is being utilised. MI UP® also has the unique ability to securely connect with your plant historian to extract real time instrument data, enabling you to develop a complete production history over time, or to re-process lost data in the event of an outage.Key Features

Customised to your plant performance

MI UP® is modelled around your specific equipment, processes and flowsheet by the experienced plant metallurgists at Metallurgical Systems, along with plant representatives, meaning all of the insights you receive are meaningful and relevant to your operations.Granular detail

Unlike other solutions, MI UP® offers a very granular level of detail regarding your plant performance – right down to individual equipment items so you can easily determine exactly where and how any losses or inefficiencies are occurring.

Flexible and scalable

MI UP® can grow and adapt with your plant. It can securely connect with your plant historian to extract real time instrument data and develop a granular qualitative production history over time, or can re-process lost data in the event of an outage. MI UP® can be implemented stand alone or integrated with MI Core® for enhanced functionality.

State of the art technology

This innovative solution leverages the latest in machine learning to automate classifications based on plant conditions. This results in operators providing only minimal input, and means you receive much deeper and richer insights than would otherwise be possible.Instant notifications

MI UP® captures data from a wide array of plant data sources and provides your maintenance, reliability or production teams with instant notifications so you can make fast decisions based on what is happening in real time.Transparency

MI UP® gives you complete transparency regarding your equipment performance and provides data driven insights about the performance of your production assets over time.The MI UP® difference

- Delay accounting/downtime capture and reporting

- Tracks downtime at equipment level

- Calculates detailed performance efficiency metrics

- Automated upstream / downstream context tracking

- Automated alerts and pre-populated classification of events

- Entirely customised to each plant

- Can be scoped and deployed 100% remotely

- Fully integrated with other data and reporting

- Redundant data capture from plant historians

- Expert training and support