AMIRA P754 Metal Accounting Software

How to use data-driven digital tools to exceed AMIRA P754 reporting guidelines.

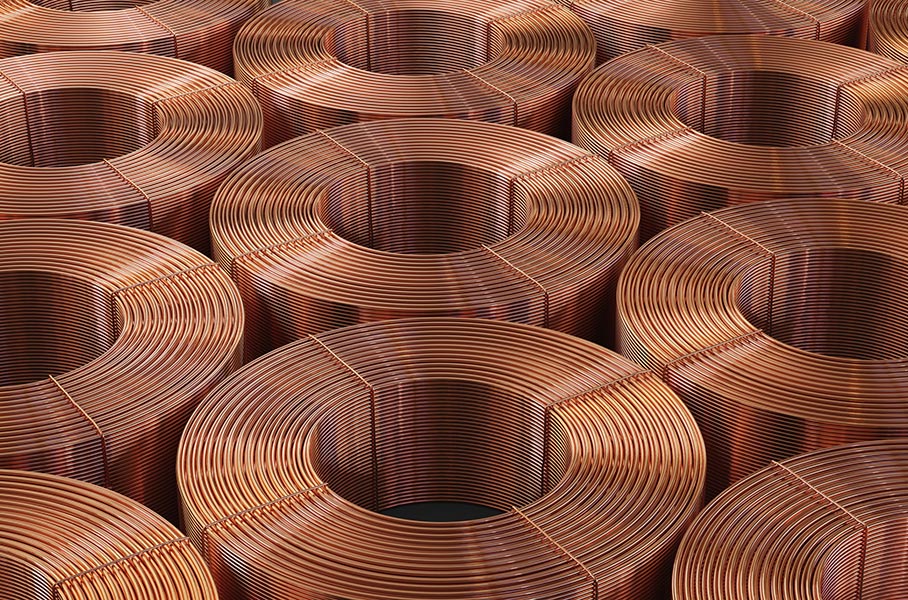

Introduction: What is AMIRA P754?

The AMIRA P754 Code of Practice for Metal Accounting is a set of governance guidelines developed by AMIRA, an independent, global, not-for-profit organisation representing the resources industry. Their guidelines establish 10 standardised metal accounting practices to ensure accurate, auditable and transparent data for improved corporate governance in mining and metallurgical companies.

This initiative, which gained momentum following significant financial scandals, has gained widespread adoption as the global standard for metal accounting and serves as the foundation for metallurgical plant audits worldwide.

Today, mineral processing plants are increasingly expected to demonstrate adherence to AMIRA P754 as part of their environmental, social and governance (ESG) compliance.

While these principles remain foundational to good governance in the mining and metals sector, the technological landscape has transformed dramatically since their establishment in 2004/2005. What was once considered best practice in metal accounting and data management has been superseded by advanced digital capabilities that enable unprecedented levels of accuracy and insight.

The implementation of accurate metal accounting delivers significant financial benefits. By understanding the data behind operations, organisations can achieve substantial gains through process optimisation and improved operational efficiency.

Related: Learn more about the evolution of the AMIRA P754 Code of Practice

What is a metal accounting system?

A metal accounting system extends far beyond software alone. As defined in the AMIRA Code, it encompasses the entire end-to-end process of metal accounting, from initial data collection methods through to calculation, reporting and auditing requirements.

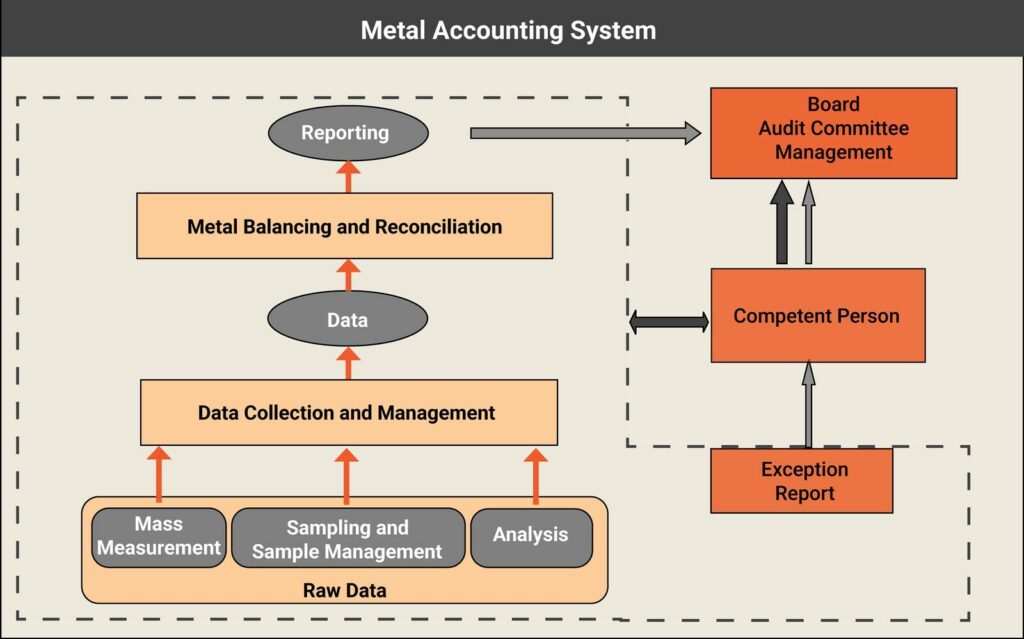

Diagram 1: Metal accounting system structure

This diagram shows the flow from raw data collection through to board-level reporting, including the critical roles of the competent person and exception reports in the governance framework.

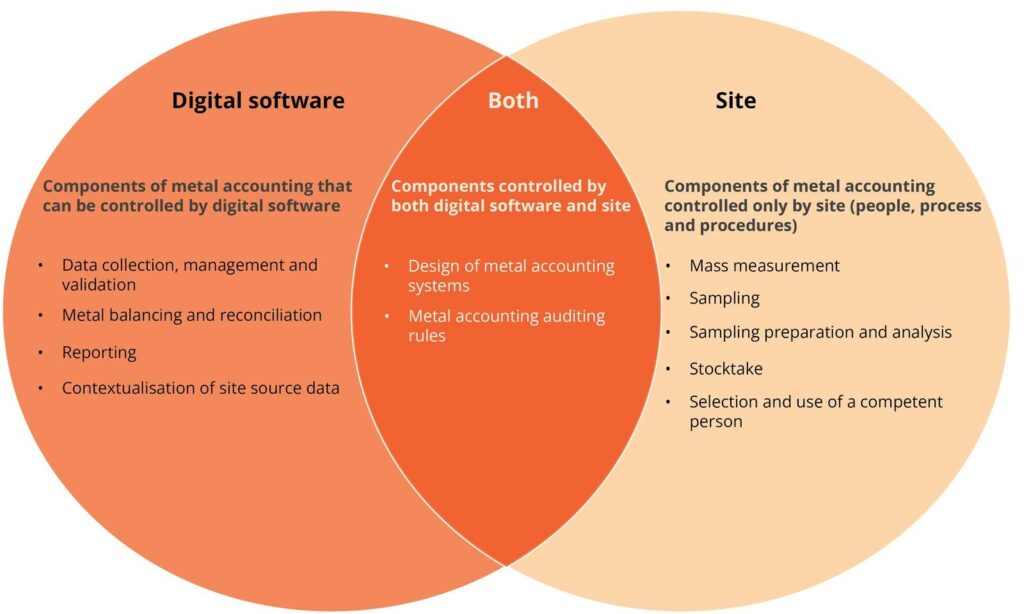

While digital software can manage many components of metal accounting, other elements rely on site-specific processes and procedures. The intersection of these digital and physical components creates a comprehensive system, as shown in the Venn diagram below.

Diagram 2: Components of metal accounting

This Venn diagram illustrates which aspects of metal accounting can be managed by digital software, which require site control, and which need both.

Related: Discover the structure of the AMIRA P754 Code and the 10 Principles

What are the components of a best-practice AMIRA P754 metal accounting solution?

Modern metal accounting requires sophisticated digital solutions that integrate data collection, advanced analytics and dynamic process simulation. Using mass and energy balances combined with advanced database structures, these solutions deliver accurate, efficient and granular tracking of metallurgical processes.

A comprehensive AMIRA P754 solution consists of six key components:

1. Source data centralisation

Centralises and digitises data from multiple sources across the plant into a single organised system, ensuring complete traceability back to source data. All information is readily accessible to authorised stakeholders through automated data flows that integrate with data historians, laboratory information management systems, mining, maintenance, environmental and other departments.

- Interoperability of data across multiple systems

- Two-way flow between Enterprise Resource Planning (ERP) systems

- Integration with third-party data sources

- Full automation of data collection

- Consistent data collection methods and timing

- Standardised data formats and structures

2. Data validation and organisation

Validates and organises centralised data through automated quality control processes that evaluate every data point against consistent rules. The system flags data that falls outside expected ranges for immediate attention, while tracking all modifications in a complete audit trail.

- Automated validation of source data for missing values and expected ranges

- Immediate flagging of major data deviations for resolution

- Quality control and quality assurance (QAQC) checks for all data types

- Individual data point quality limits to account for variations

- Complete tracking of data corrections with justification

- Automated handling of missing data through interpolation where appropriate

3. Dynamic simulation

Creates a dynamic model of your specific process to produce a comparative dataset through mass and energy balance calculations. This is superior to traditional approaches like statistical data reconciliation, as it uses time as a dimension to measure inventory, track intermediate streams and cross-check measured plant source data without node boundaries or user assumptions. The simulation incorporates detailed chemical engineering principles including residence times and reaction chemistry, for comprehensive process understanding.

- Complete automation enabling hourly plant-wide mass and energy balance

- Time-based simulation accounting for process dynamics

- Cross-checking of measured results against calculated results

- Verification of data through multiple inputs and cross-references

- Detailed tracking of inventory and intermediate streams

- Complex chemistry modelling including residence times and reactions

- Metal transfer tracking throughout the process

- No artificial boundaries across process nodes

- Elimination of user assumptions in mass balance calculations

4. Data warehouse

Uses a high-performance, structured database to store large volumes of measured and calculated data. The system provides secure, stable access to pre-aggregated data across multidimensional tables, ensuring data integrity while enabling fast analysis.

- Secure and stable database structure

- Access to large amounts of pre-aggregated data

- Multidimensional table organisation

- High-performance data retrieval

- Structured storage of both measured and calculated values

5. Advanced analysis, data visualisation and reporting

Delivers accurate, automated reports for stakeholders across the organisation. Breaking down data silos, the system provides authorised users with ready access to user-friendly data and analysis tools, enabling fast decision-making and prompt action.

- Automated reporting across various timeframes with integrated approvals processes

- Mass and energy balance reports

- Production reporting

- Process optimisation analysis

- Sustainability and ESG reports

- User-friendly data visualisation

- Accessible to authorised users across the organisation

- Real-time decision support

6. Training and support

Provides comprehensive training through an online learning management system, helping stakeholders develop the skills and understanding needed to maximise solution value. Supported by an expert team of metallurgists and engineers providing ongoing technical guidance online or in person.

- Online learning management system with step-by-step modules

- Custom training pathways for different user roles

- Additional support courses featuring advanced tips and techniques

- Expert metallurgist and engineering team support

- Regular knowledge updates and best practices

7. Software-as-a-Service (SaaS) Deployment

Available as a flexible SaaS solution that combines deep customisation and security with cloud-based scalability and transparency. This deployment model eliminates capital expenditure while ensuring continuous access to the latest innovations.

- Instant software improvements and upgrades

- Seamless scalability across multiple sites

- Transparent, flexible pricing model

- No internal IT resource requirements

- Cloud-based security and accessibility

- Full customisation to site-specific processes

- Comprehensive data migration and integration

- Ongoing expert management and support

From the experts

Many experienced industry experts make a strong case for modern metal accounting technology:

Your digital roadmap to AMIRA compliance

Whether you are just starting your AMIRA P754 implementation or already have existing metal accounting processes in place, modern digital solutions can help at every stage.

For mining and minerals organisations, Metallurgical Systems recommends a staged approach to AMIRA P754 compliance that starts with a feasibility study and progresses through to implementation and advanced functionality from our extension modules.

There are four broad steps in the recommended roadmap that align with our AMIRA P754 reporting software and compliance solutions:

Our team works with operations to understand current processes and requirements, determining the optimal path to AMIRA P754 compliance.

A review of existing instrumentation, sampling processes, technology and workflow processes is conducted.

An implementation plan is created with a proposed project schedule, recommendations and estimated costs.

Once implementation has been approved, we start with automated data capture and data quality analysis.

This includes data cleansing, organisation and validation tools (using machine learning).

The next step is implementing dynamic simulation, configured to your site’s specific process chemistry and thermodynamics, performing automated site-wide mass and energy balance.

We create data sets for measured, corrected and calculated data, contextualising your measured data for process optimisation and accurate metallurgical accounting.

A user-friendly control panel is used to manage the metallurgical accounting solution.

Changes to internal processes and procedures around metallurgical accounting and production reporting are implemented.

Training:

Online learning management system.

Step by step training to help stakeholders have the skills and understanding they need to get the most from the solution.

Additional support courses with tips on features.

Support:

Access to an expert team of metallurgists and engineers with onsite training available.

Maintenance:

Includes software updates, new features to deliver best in class metallurgical accounting and process optimisation.

Enhance functionality with MI extension modules:

MI Sustainability

Data-driven sustainability reporting, compliance and ESG optimisation.

MI Scenario®

Predict the future using data from the past.

MI UP®

Maximise the effectiveness and life of your plant equipment.

MI Process Optimiser®

Optimise your plant’s processes based on intelligent data.

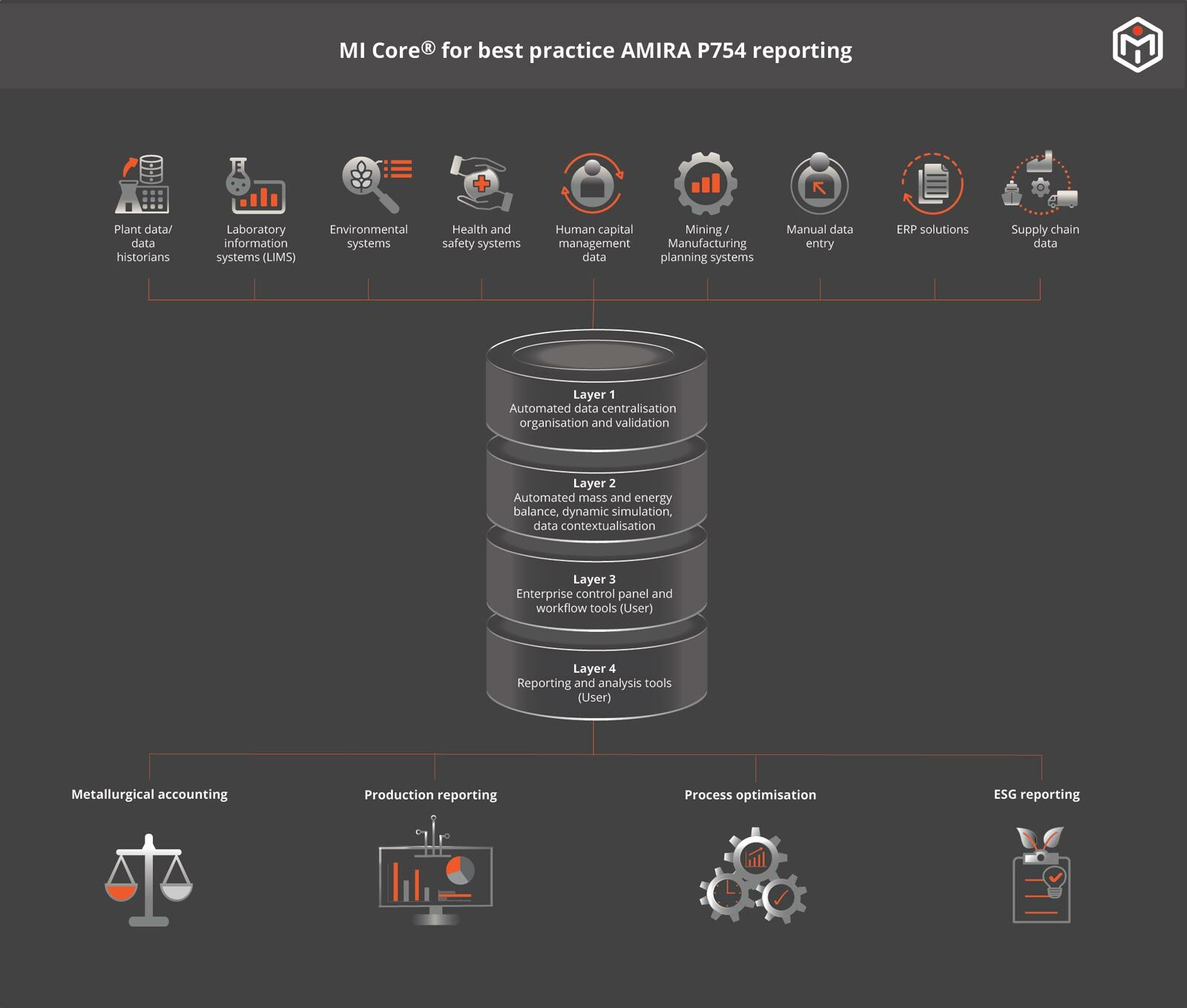

Using MI Core® for best practice AMIRA P754 reporting

MI Core® integrates all data inputs through a four-layer processing system to deliver comprehensive outputs across metallurgical accounting, production reporting, process optimisation and ESG reporting. This structured approach ensures compliance with AMIRA P754 principles while providing actionable insights.

Learn more: Explore detailed examples of how MI Core® exceeds each AMIRA P754 principle

MI Core®: Your proven shortcut to best-practice metal accounting

The demands of AMIRA P754 compliance – requiring accurate, auditable metallurgical accounting across thousands of measure points – mean that advanced data-driven technology is essential for both governance and operational benefits.

Manual systems and spreadsheets cannot capture or process the volumes of data needed to deliver immutable, unalterable and auditable reports.

The good news is that MI Core® – part of the award-winning, industry-leading Metallurgical Intelligence suite of solutions – solves these challenges through comprehensive metallurgical accounting, production reporting and process optimisation capabilities.

The platform captures, centralises, consolidates and validates massive volumes of disparate source data fast – so you can start running mass and energy balance calculations at speed.

Plus, with MI Core®, it’s easy to keep pace with the broader evolving finance-grade sustainability reporting requirements for direct and indirect emissions (scopes 1, 2 and 3), energy and water consumption, and other key sustainability metrics like waste, recycling and air quality.

Used across the globe, MI Core® is available in multiple languages including English, French, Spanish and Chinese.

MI Core® delivers:

- Near real-time insights

- Single source of centralised, validated, organised and integrated plant-wide data

- Accurate plant-wide mass and energy balance configured to your exact process as a digital replica of your operations

- Contextualise your measured source data with model calculated data

- Track product batches at every step of the process – at/between sites from pit to port

- Accurately track and report sustainability data to reduce emissions and waste

- Drive efficiency by automating manual tasks

- Track, simulate, test, analyse and forecast scenarios

- Future-proof technology delivered in a scalable cloud-based SaaS platform

Take control of your AMIRA P754 Metal Accounting

To learn how MI Sustainability can help you meet your PCF reporting obligations and minimise emissions, energy, water and waste across your supply chain, contact our expert team on +61 2 7229 5646 or info@metallurgicalsystems.com.

About the Authors

This article has been collaboratively authored by the team at Metallurgical Systems, and fact-checked and authorised by Managing Director and industry specialist John Vagenas.