NGER and Safeguard Mechanism Reporting Software

Data-driven solutions to meet your NGER and Safeguard Mechanism compliance obligations

Australia’s National Greenhouse and Energy Reporting (NGER) scheme and Safeguard Mechanism are evolving rapidly, with the Climate Change Authority’s 2023 review making 25 recommendations that the Australian Government has largely accepted, signalling increased data management requirements.

For mining and resources operations – among Australia’s most emissions-intensive industries – these frameworks demand accurate, auditable data across complex processing chains. Traditional spreadsheets and manual calculations no longer meet today’s compliance standards.

Drawing on over a decade of experience developing metallurgical intelligence software for mining operations globally, this page explains how purpose-built digital solutions can streamline NGER and Safeguard Mechanism obligations through automated data capture, validation and advanced metallurgical accounting.

What is the National Greenhouse and Energy Reporting (NGER) Scheme?

The National Greenhouse and Energy Reporting Act 2007 (NGER Act) established Australia’s primary framework for reporting company information about greenhouse gas emissions, energy production and energy consumption.

Established to inform government policy, provide transparency to the Australian public and meet international reporting obligations, the NGER scheme is a critical part of Australia’s response to the global demand for climate initiatives.

The NGER Act comprises three key components:

- National Greenhouse and Energy Reporting Scheme: The mandatory reporting framework for emissions, energy production and consumption

- Safeguard Mechanism: Requires Australia’s largest emitters to keep net emissions below their baselines

- Administration, Compliance and Audit Framework: Ensures accuracy and accountability in reporting

Who needs to report under NGER?

Companies must report under NGER if they meet specific corporate group or facility thresholds related to emissions and energy:

Corporate group thresholds:

- 50 kilotonnes (kt) CO₂-e of combined Scope 1 and Scope 2 emissions

- Production of 200 terajoules (TJ) of energy

- Consumption of 200 TJ of energy

Facility thresholds:

- 25 kt CO₂-e of combined Scope 1 and Scope 2 emissions

- Production of 100 TJ of energy

- Consumption of 100 TJ of energy

If corporate group thresholds are met, all facilities within the group must report, regardless of individual facility thresholds.

1. National Greenhouse and Energy Reporting Scheme

2 instruments:

- National Greenhouse and

Energy Reporting Regulation 2008 - National Greenhouse and Energy Reporting (Measurement) Determination

2008

2. Safeguard Mechanism

1 instrument:

- National Greenhouse and

Energy Reporting (Safeguard Mechanism) Rule 2015

3. Administration, Compliance and Audit Framework

2 instruments:

- National Greenhouse and Energy Reporting (Audit) Determination 2009

- National Greenhouse and Energy Reporting (Auditor Registration Instrument 2019)

What is the Safeguard Mechanism?

The Safeguard Mechanism is a framework for reducing emissions from Australia’s largest industrial facilities over time, supporting Australia’s targets of 43% emissions reduction below 2005 levels by 2030 and net zero by 2050.

Following significant reforms in 2023, the Safeguard Mechanism now requires facilities to reduce their net emissions in line with Australia’s climate targets, marking a shift from reporting to actual emissions reduction.

Key outcomes of the Safeguard Mechanism include:

- Ensuring net covered emissions from facilities don’t exceed their baselines

- Limiting total net safeguard emissions between 2020-2030 to 1,233 Mt CO₂-e

- Reducing net safeguard emissions to no more than 100 Mt CO₂-e by 2029-30 and zero after 30 June 2049

- Implementing declining facility baselines with a default rate of 4.9% per year through to 2029-30

- Creating material incentives for responsible emitters to invest in reducing covered emissions

- Supporting trade-exposed industries’ competitiveness during the transition to a net zero economy

Who must comply with the Safeguard Mechanism?

The Safeguard Mechanism applies to facilities that emit more than 100,000 tonnes of carbon dioxide equivalent (CO₂-e) annually. This primarily includes facilities in mining, oil and gas extraction, manufacturing and waste sectors.

What needs to be reported under NGER and the Safeguard Mechanism?

Understanding the specific reporting requirements for both NGER and the Safeguard Mechanism is essential for compliance. As outlined by the Climate Change Authority’s 2023 NGER Review, the following elements must be reported under each framework.

NGER Reporting Requirements

Scope 1 Emissions:

- Direct emissions arising from energy (including fuel combustion and fugitive emissions), industrial processes and waste

- Not included: Agriculture, land use changes, forestry, private vehicle transport and residential sectors

- Only reportable if there is a relevant method in the Measurement Determination for estimation

- Four available methods for estimating Scope 1 emissions:

- Method 1: Default method using emissions factors

- Method 2: Facility-specific sampling with Australian/international standards for analysis

- Method 3: Facility-specific information applying standards to both sampling and analysis

- Method 4: Direct monitoring or measuring of emissions (periodic or continuous)

Scope 2 Emissions:

- Reportable for electricity consumed from the main grid, other networks or direct connections

- Includes purchased heating, cooling or steam

- Two compulsory location-based calculation methods:

- Method A1: For the main electricity grid

- Method A2: For other electricity networks

- Optional market-based Scope 2 emissions reporting introduced in 2023

Scope 3 Emissions:

- Not currently reportable under NGER

- The Climate Change Authority’s 2023 review recommends studying how to use NGER data to facilitate Scope 3 emissions estimation

Energy Consumption:

- Total energy content consumed from various fuels and energy commodities

- Total electricity consumption

Energy Production:

- Total energy produced from fuels or other energy commodities

- Electricity production for qualifying generators

Reporting Cycle:

- Annual reports submitted electronically through the Emissions and Energy Reporting System (EERS)

- Submission deadline: 31 October each year

Safeguard Mechanism Reporting Requirements

Scope 1 Emissions:

- Safeguard baselines calculated on Scope 1 emissions for facilities exceeding 100 kt CO₂-e per year

- Excess emissions must be managed when baselines are exceeded

- Baselines set using production-adjusted (intensity) framework as of 2023-2024

- Indirect emissions (Scope 2 and 3) not included in the Safeguard Mechanism threshold

Your digital roadmap to NGER and Safeguard Mechanism compliance

Whether you have been using manual emissions reporting processes or if you are new to NGER and/or Safeguard Mechanism reporting, digital reporting software can help at every stage.

Starting by centralising your data, the right digital tools are the only way to address today’s mandatory NGER requirements, adapt to evolving frameworks, and help set and achieve decarbonisation targets and declining baselines.

For complex industrial processes, Metallurgical Systems recommends a staged approach to digitally transform NGER and Safeguard Mechanism reporting that starts with meeting mandatory compliance rules and moves towards advanced capabilities and emissions reduction strategies to reduce your baseline emissions.

There are four broad steps in the recommended roadmap to digitally transform your NGER and Safeguard Mechanism reporting:

Deploy reporting software to centralise data and use templates to meet today’s compliance regulations.

Set up the systems needed for centralised records that capture the in-depth NGER and Safeguard Mechanism data points needed to report to changing requirements over time.

On top of centralised data, the next step is to add automated data capture and data quality to your NGER and Safeguard Mechanism reporting.

This includes data cleansing, organisation and validation tools (using AI/ML) and advanced visualisation tools to deliver dynamic, accurate and auditable near real-time NGER and Safeguard Mechanism reporting.

Beyond automation, the next step is enabling finance-grade emissions reporting and automated validation of NGER and Safeguard Mechanism data against plant operations data using a mass and energy balance configured to your site/s.

You can report according to the NGER and Safeguard Mechanism reporting boundaries at a very granular level.

The final step is adding the granular analysis needed to plan, execute and evaluate your decarbonisation roadmap and adapt to evolving industry standards and declining baselines.

Running a steady-state simulation of your asset, validated finance-grade data is used to enable complex forecasting, transition planning, scenario analysis and decarbonisation assessments.

You can then adjust inputs and compare final production, emissions and consumption using advanced visualisation tools.

Why digital reporting is the only solution for NGER and Safeguard Mechanism reporting

Governments around the world are progressing with ambitious policy and legislation to report and reduce emissions. Data-driven technology is the only solution to meet the NGER and the Safeguard Mechanism reporting requirements.

Manual spreadsheets cannot capture or process the volumes of data needed to deliver immutable, unalterable and auditable NGER and Safeguard Mechanism reports.

The good news is that digital tools proven to solve these data challenges for complex industrial processes, like mining and resources, are available.

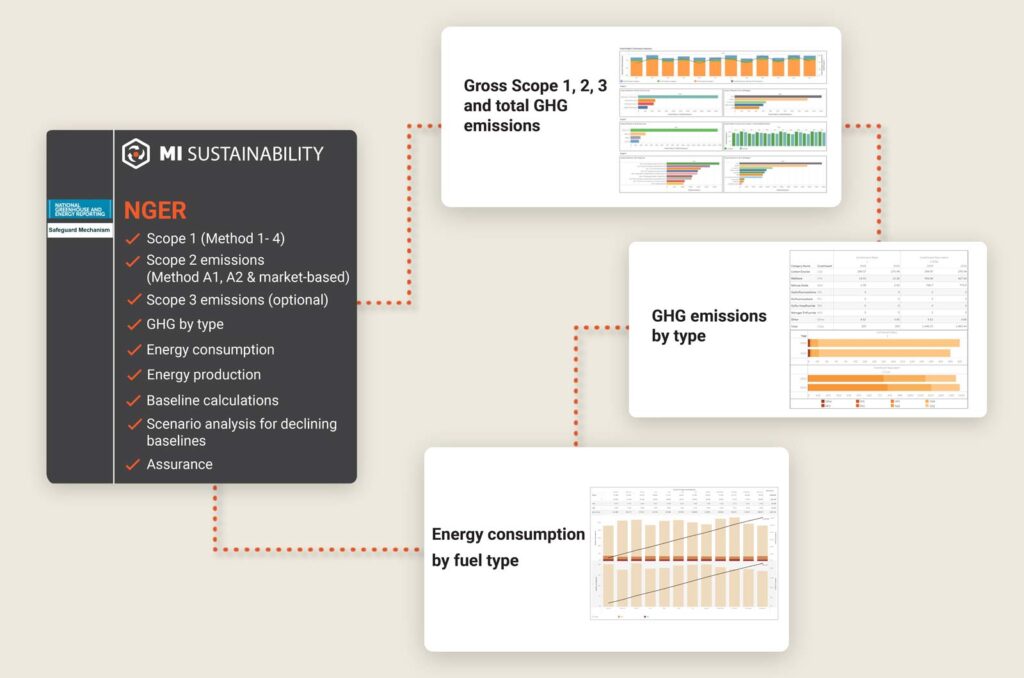

MI Sustainability, as part of the Metallurgical Intelligence® suite of solutions, is an established platform that centralises plant-wide data and dynamically simulates your processing operation as a digital twin.

It performs a plant-wide mass and energy balance, and analyses all Scope 1, 2 and 3 emissions data to deliver granular reports that are mapped to the NGER and Safeguard Mechanism reporting fields.

MI Sustainability addresses key risk areas for high-emissions facilities by determining facility boundaries accurately, capturing all activities required for NGER reporting, calculating and verifying data according to NGER measurement determination, keeping time-series data records required before and after the trigger year, and confirming production variable metrics align with the Safeguard Mechanism Document Schedule 1.

Examples of using MI Sustainability NGER and Safeguard Mechanism reporting software

The following examples demonstrate how the MI Sustainability NGER and Safeguard Mechanism reporting software can satisfy compliance regulations and help achieve decarbonisation goals with granular reports that can map directly to the data points required.

Scopes 1, 2 and 3 reporting

Scope 1 and 2 emissions must be reported at the facility level.

Only activities that have an applicable method in the NGER Measurement Determination are to be reported.

MI Sustainability can accurately measure and report Scopes 1, 2 and 3 across your value chain and adjust organisational boundaries as per the NGER reporting requirements. Emissions can be measured at the facility and the activity level.

Scope 3 reporting is not mandatory, however can be broken down into categories

Types of greenhouse gases

Greenhouse gases reported under the National Greenhouse and Energy Reporting (NGER) Scheme include:

- carbon dioxide (CO2)

- methane (CH4)

- nitrous oxide (N2O)

- sulphur hexafluoride (SF6)

- specified kinds of hydrofluorocarbons and perfluorocarbons.

MI Sustainability can measure various greenhouse gases by facility and activity

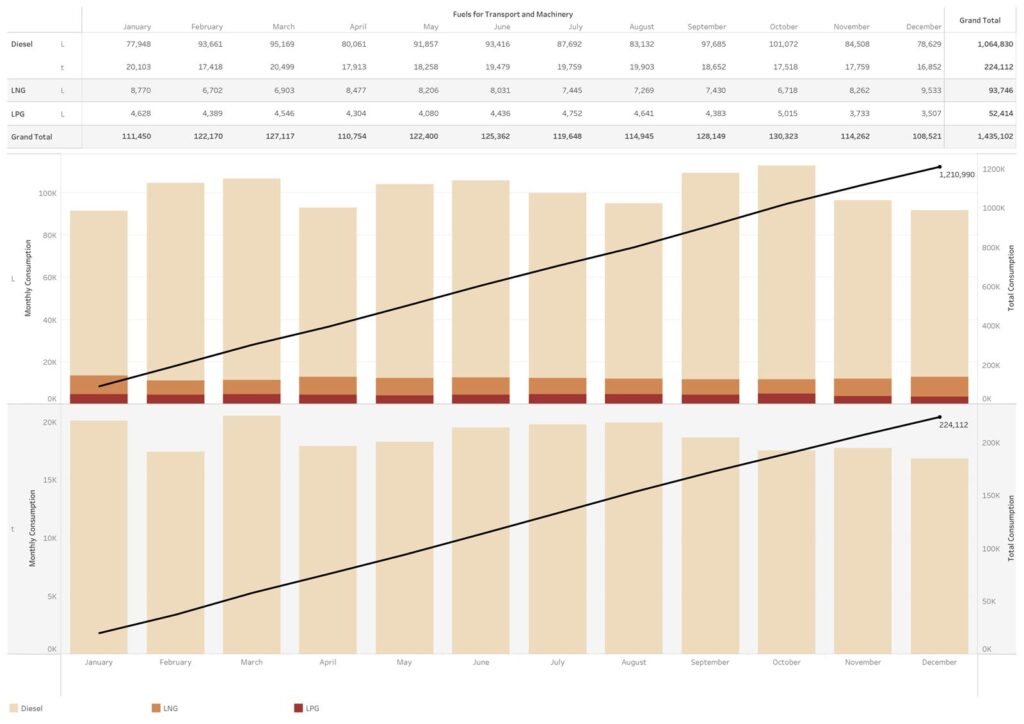

Energy consumption and energy production

Types of energy reported under NGER include:

- fossil fuels and coal-based products

- fuels derived from recycled materials

- biogases

- petroleum-based oils and greases

- biofuels.

Behind aggregated data for NGER emissions reporting are the consumption data for each category and fuel type.

Fuels for transport and machinery

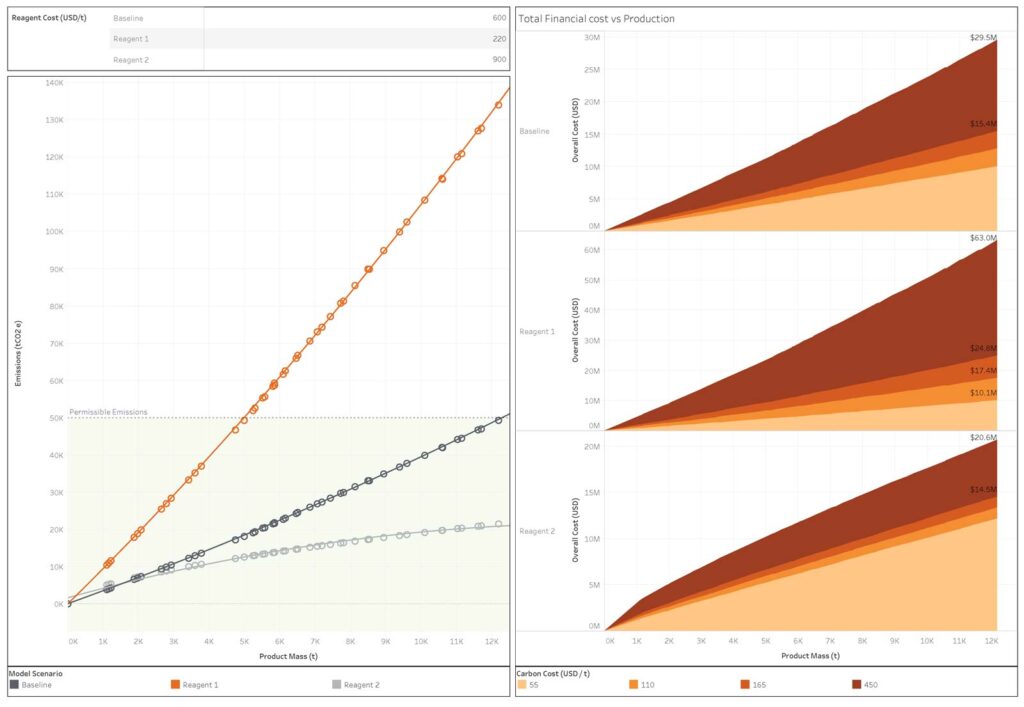

Declining baselines

Safeguard Mechanism reforms require standard and landfill facility baselines to decline by 4.9% each financial year through to 30 June 2030.

Standard baselines are determined based on the amount of product each facility produces in a financial year.

MI Sustainability can measure and report your production and calculate your baseline.

MI Sustainability can use scenario analysis to determine how you can achieve declining baselines.

In the example below, total emissions from using different reagents have been calculated compared to a set baseline, including the associated cost to the organisation.

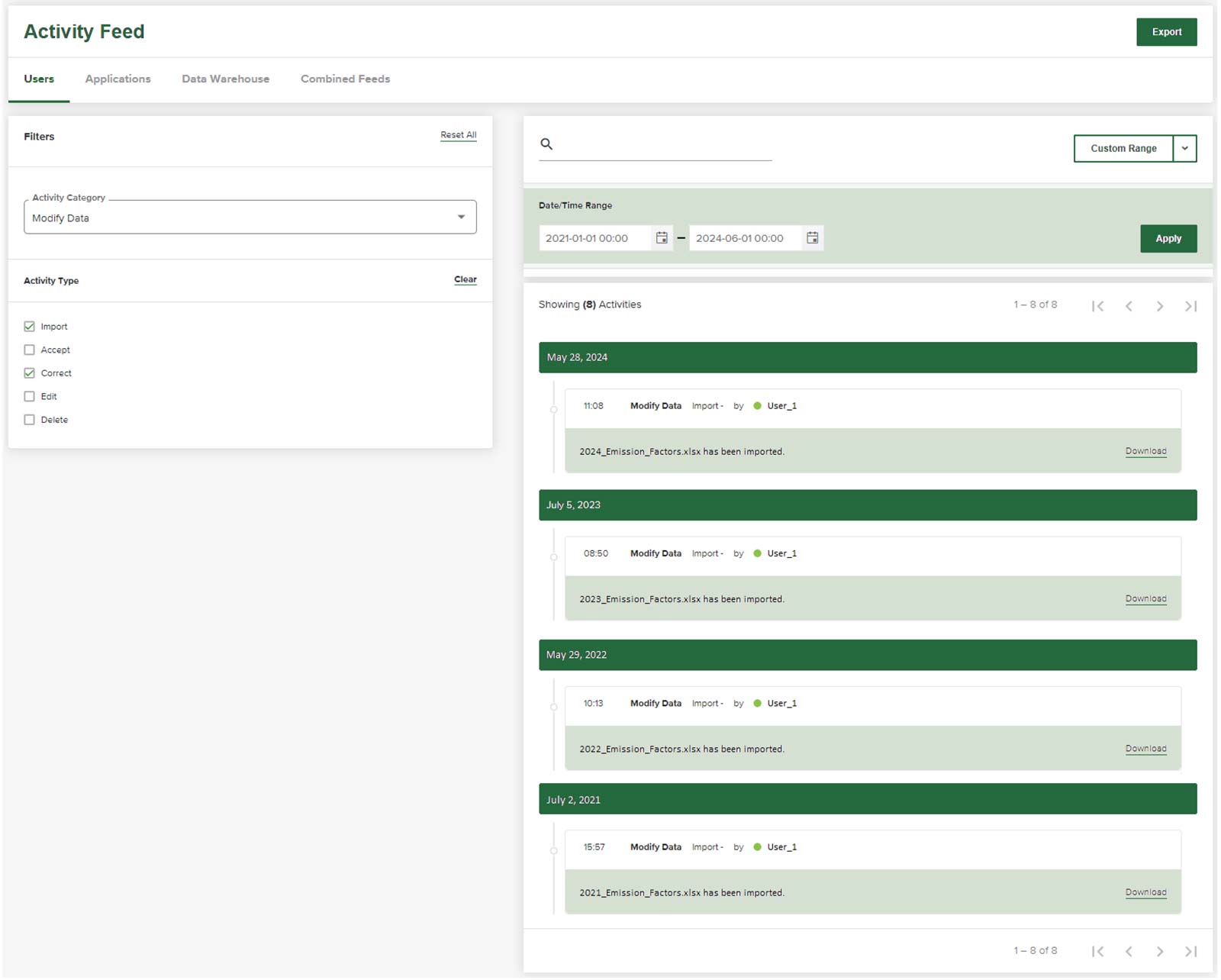

NGER and Safeguard Mechanism Audits

Audits are used to:

- verify an application or report

- ensure scheme participants are complying with legislation

- support the broader compliance monitoring strategy

Example of an MI Sustainability Assurance Report

For complete assurance, organisations should demonstrate that they can track NGER and Safeguard Mechanism calculations back to source data such as instrumentation data and follow an audit trail to the reported values.

This is an example of the audit trail in the MI Sustainability activity feed that details any changes or modifications to data.

NGER and Safeguard Mechanism Frequently Asked Questions

Why are spreadsheets no longer sufficient for NGER and Safeguard Mechanism reporting?

Spreadsheets cannot reliably handle the volume and complexity of data required for NGER and Safeguard Mechanism compliance. They lack automated data capture, robust validation capabilities, audit trails and the ability to perform complex mass and energy balance calculations. As reporting requirements become more stringent, the risk of errors, inconsistencies and non-compliance increases significantly with manual spreadsheet-based approaches.

What is the National Greenhouse and Energy Reporting (NGER) Scheme and the Safeguard Mechanism?

The NGER Scheme is Australia’s primary framework for reporting company information about greenhouse gas emissions, energy production and energy consumption. The complementary Safeguard Mechanism requires Australia’s largest industrial facilities (emitting more than 100,000 tonnes of CO₂-e annually) to keep their net emissions below declining baselines that reduce by 4.9% annually through to 2030, driving actual emissions reductions in line with Australia’s climate targets.

Who needs to report under NGER and the Safeguard Mechanism?

Companies must report under NGER if they meet corporate thresholds (50 kt CO₂-e emissions, 200 TJ energy production/consumption) or facility thresholds (25 kt CO₂-e emissions, 100 TJ energy production/consumption). The Safeguard Mechanism applies specifically to facilities emitting more than 100,000 tonnes of CO₂-e annually, primarily in mining, oil and gas, manufacturing and waste sectors.

How does MI Sustainability help with NGER and Safeguard Mechanism reporting?

MI Sustainability provides a comprehensive digital solution that centralises data from across your operations, performs plant-wide mass and energy balances, automates calculations using approved methodologies, maintains complete audit trails and generates accurate reports that map directly to NGER and Safeguard Mechanism requirements. The platform enables scenario analysis for declining baseline planning and supports the transition to lower emissions through data-driven insights.

What benefits does MI Sustainability offer beyond compliance?

Beyond meeting compliance requirements, MI Sustainability provides valuable insights for emissions reduction planning, helps identify cost-saving opportunities, supports scenario analysis for future planning, enables transparent reporting to stakeholders and prepares your organisation for evolving sustainability reporting frameworks. The platform’s ability to simulate different operational scenarios is particularly valuable for planning how to meet declining Safeguard Mechanism baselines.

MI Sustainability: Your proven fast-track sustainability reporting solution

Designed to navigate multiple global reporting frameworks and many separate ESG performance indicators, MI Sustainability is a uniquely flexible and comprehensive sustainability reporting solution for today, and the future.

Whether you are just starting your sustainability journey or already have sustainability reporting and compliance processes and targets in place, MI Sustainability has flexible packages for every stage.

The benefits span from ticking sustainability compliance boxes on our Standard Package right through to advanced environmental, social and governance (ESG) capabilities on our Expert and Enterprise Packages:

- Track end-to-end sustainability indicators spanning Scopes 1, 2 & 3, and Climate & Nature

- Single source of centralised, validated, organised and integrated sustainability data

- Accurate asset-wide mass and energy balance customised to your exact process as a digital replica of your operations

- Contextualise your measured activity data using source data as inputs

- Analyse, track and report activity data right down to a product level

- Track and consolidate on-site and off-site renewable energy sources

- Capture and report on data directly related to the mining asset it has been implemented in, including integration with third-party data

- Track, simulate, test, analyse and forecast scenarios

- Future-proof technology delivered in a scalable cloud-based SaaS platform

Take control of your NGER and Safeguard Mechanism reporting

To learn how MI Sustainability can help you meet your NGER and Safeguard Mechanism reporting obligations and minimise emissions, energy, water and waste across your supply chain, contact our expert team on +61 2 7229 5646 or info@metallurgicalsystems.com

About the Authors

This article has been collaboratively authored by the team at Metallurgical Systems, and fact-checked and authorised by Managing Director and industry specialist John Vagenas.