Metallurgical Engineering Internships in Sydney

Internship opportunities

We are proud to provide opportunities to the next generation of technical professionals and have hosted several paid interships for some very high quality candidates who have then gone on to work full time for us.

Metallurgical Systems Internship 2024 - Chemical Engineer or Chemical Product Engineer

Are you a motivated undergraduate chemical engineer/chemical product engineer looking for a paid summer internship position? Do you have great attention to detail and a passion for technology?

We are currently looking for a talented student to join our team. The ideal candidate will be currently in their penultimate year of study (third or fourth year) of a chemical engineering/chemical product engineering or related degree. You will be based in our office in Surry Hills, Sydney near Central station, and have the chance to work on a suite of highly innovative software that’s used in some of the most successful mining plants around the world.

Metallurgical Systems is very passionate about looking after our employees. You will have the chance to work in a diverse, cross-cultural team, and be an integral part of a project’s success. This is an ideal opportunity to grow and expand your skills and be mentored by highly accomplished metallurgists – many of whom are recognised as experts in their field.

About the role?

As an intern chemical engineer/chemical product engineer, you will help with Metallurgical Systems’ technical projects with a focus on steady state and dynamic simulation. These projects can range from large-scale concentrators, smelters and complex hydrometallurgical facilities. We will provide extensive on-the-job training and opportunities to gain new skills and competencies. While you will be working closely with our metallurgists and engineers, you will also be working with the software development team and interacting with suppliers and clients. You will be challenged to think critically by analysing metallurgical data, performing mass balances using simulation software, and building dashboards using the most current data analysis and visualisation tools.

To apply for the position, please send us an email with your CV and academic transcript by Friday, 9th August 2024.

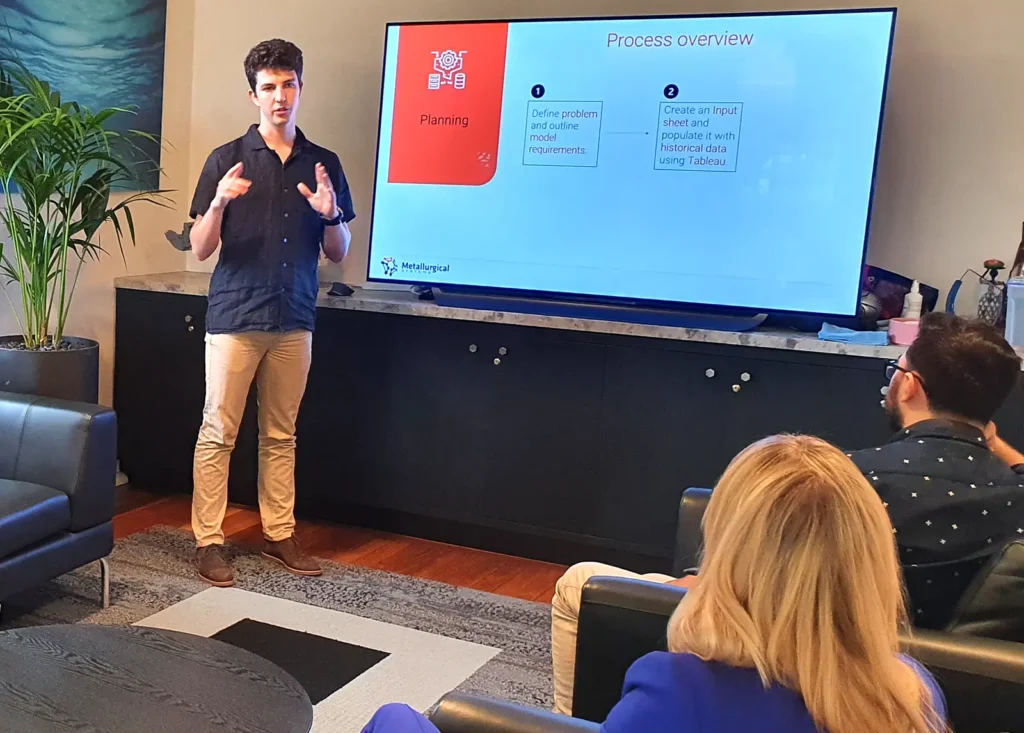

What’s it like to be an intern at Metallurgical Systems?

“My primary goal during this internship was to further develop and utilise my existing skills and knowledge that I have learnt at university in a real-world fluid and dynamic environment. I aimed to learn something new every day, and to be open to all new learning experiences and feedback.

My time at Metallurgical Systems allowed me to go above and beyond my goal. The company’s open and friendly environment, comprised of experts in the metallurgical field, fostered a unique learning experience that allowed me to learn, challenge myself and contribute to a shared objective.”

– Matthew Bradely

“I helped model a concept design for a plant that recovers battery grade lithium from waste residue generated at another process plant. I constructed flowsheets using client specifications and applied chemical and thermodynamic principles to the modelling of units such as autoclaves and heat exchangers.

I’ve learnt an incredible amount from being surrounded by highly experienced engineers who were always willing to answer questions and provide support.

The team really challenged me to improve my engineering mindset and taught me how to approach problems beyond the scope of anything I’d encountered in university projects.”

– Gabrielle Burges

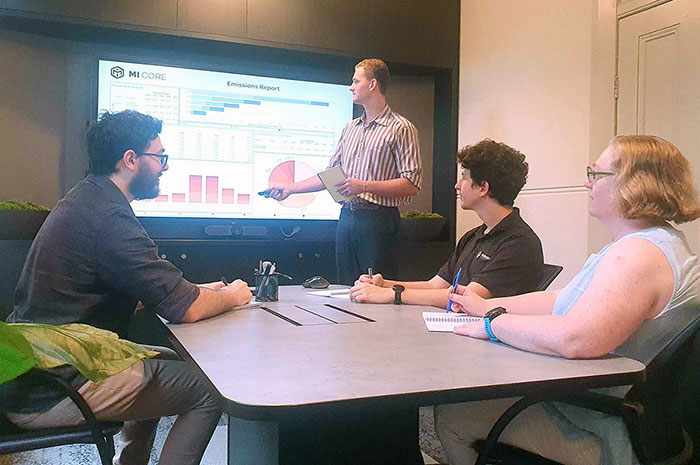

“I was assigned a project to convert a dynamic model into a working steady state model for a concentrator.

My work involved using process simulation software, MI Core®, MI Scenario® and advanced reporting and analysis tools. Learning to use the software was challenging. However, after I became accustomed, not only did I gain a working understanding of the software, but I began seeing the interconnection between all of them.

Throughout my placement, I was given the opportunity to connect with senior engineers and ask questions in a professional setting. I was well-supported and gained many insights into critical thinking in engineering, the significance of metallurgical accounting and the mining and minerals industry.”

– Cameron Suen

“I surprised myself with how much I achieved during my internship. I finished a steady state model for use in a real plant, created multiple reports for clients all over the world and gained a deeper understanding into the importance of data in this field. I am so excited to continue my journey at Metallurgical Systems as I complete my final year of university, with all these new skills under my belt.”

– Joshua Chapman