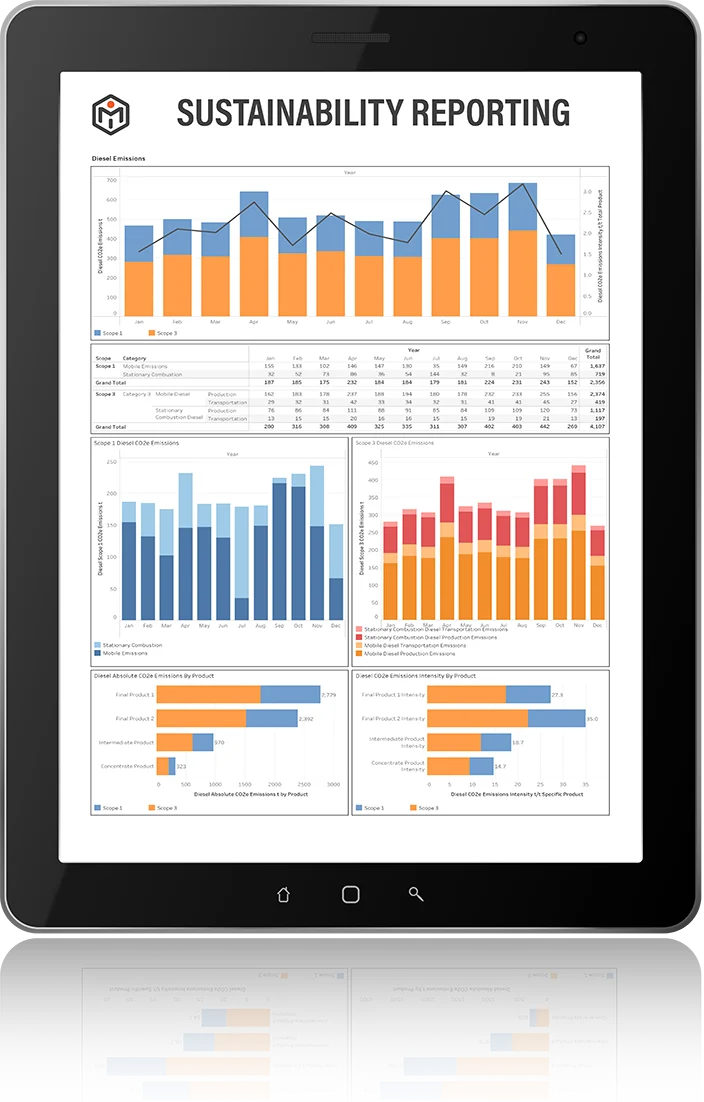

Sustainability & ESG Reporting

Track indicators such as GHG emissions (Scopes 1, 2 & 3), water, energy, air quality, waste, hazardous materials, pollutants and nature-related risk factors with proven assurance from the world’s only sustainability analytics solution for minerals and mining.

A new era of legislated accountability is here

Across the world, governing organisations and market sentiment are aligning to demand sustainability reporting transparency and climate and nature risk disclosure.

To help deliver clarity and accelerate change, a new GRI Sector Standard for mining is in development to improve the quality of reporting across the sector. This is on the back of new global standards driven by the International Sustainability Standards Board (ISSB) and leading EU bodies – with input from 20+ international governing agencies – that will require public annual reporting on emissions and demonstrated strategies to reduce them.

The ISSB and many EU bodies will also require organisations to deliver detailed climate scenario analysis as part of their sustainability reporting to demonstrate climate resilience and risks.

In many jurisdictions, auditable granular sustainability reporting will be demanded down to a product level, including disclosures on carbon, water, waste, energy and other sustainability indicators to meet evolving compliance regulations. Innovative miners are embracing intelligent digital tools to meet this challenge.

“GRI separately recommend leveraging digital technologies to address ESG data gaps. These include using artificial intelligence tools such as machine learning, artificial neural networks and natural language processing tools to forecast impacts on organisations, as well as the organisational impact on the environment and society, under different climate scenarios.”

Responsible Investor Incoming GRI chair ‘strongly urges’ Australia to choose EU standards over ISSB, 2023

Opportunities to lead the way

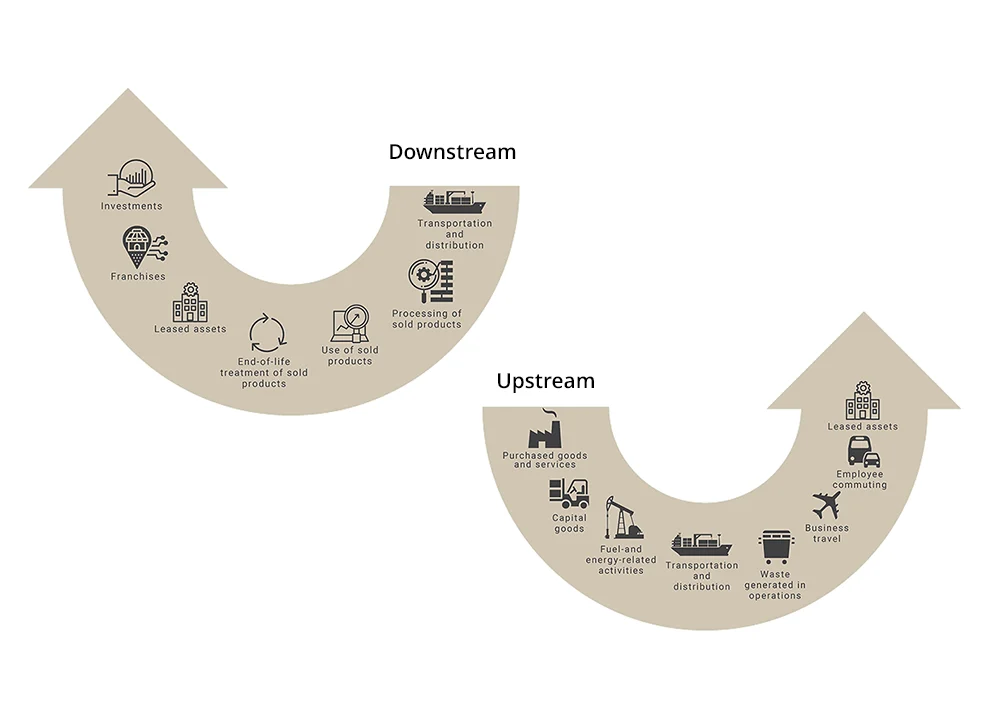

Complex industrial processes liking mining require a specialised approach to sustainability reporting. The need for a granular mass balance tracking at every step of the production process across the value chain demands advanced digital tools.

For innovative organisations willing to embrace the new data-driven era and move fast there are significant growth opportunities.

- Position your organisation as a sustainability leader

- Meet your compliance and sustainability goals

- Attract premium talent, partners and capital

- Unlock new opportunities as a green supplier

- Reduce operation costs and inefficiencies

“To ensure companies are providing reliable information, they will be subject to independent auditing and certification. Financial and sustainability reporting will be on an equal footing and investors will have comparable and reliable data. Digital access to sustainability information will also have to be guaranteed.”

European Parliament: Sustainable economy: Parliament adopts new reporting rules for multinationals, 2022

Your proven fast-track sustainability reporting solution

Introduction to MI Core ®

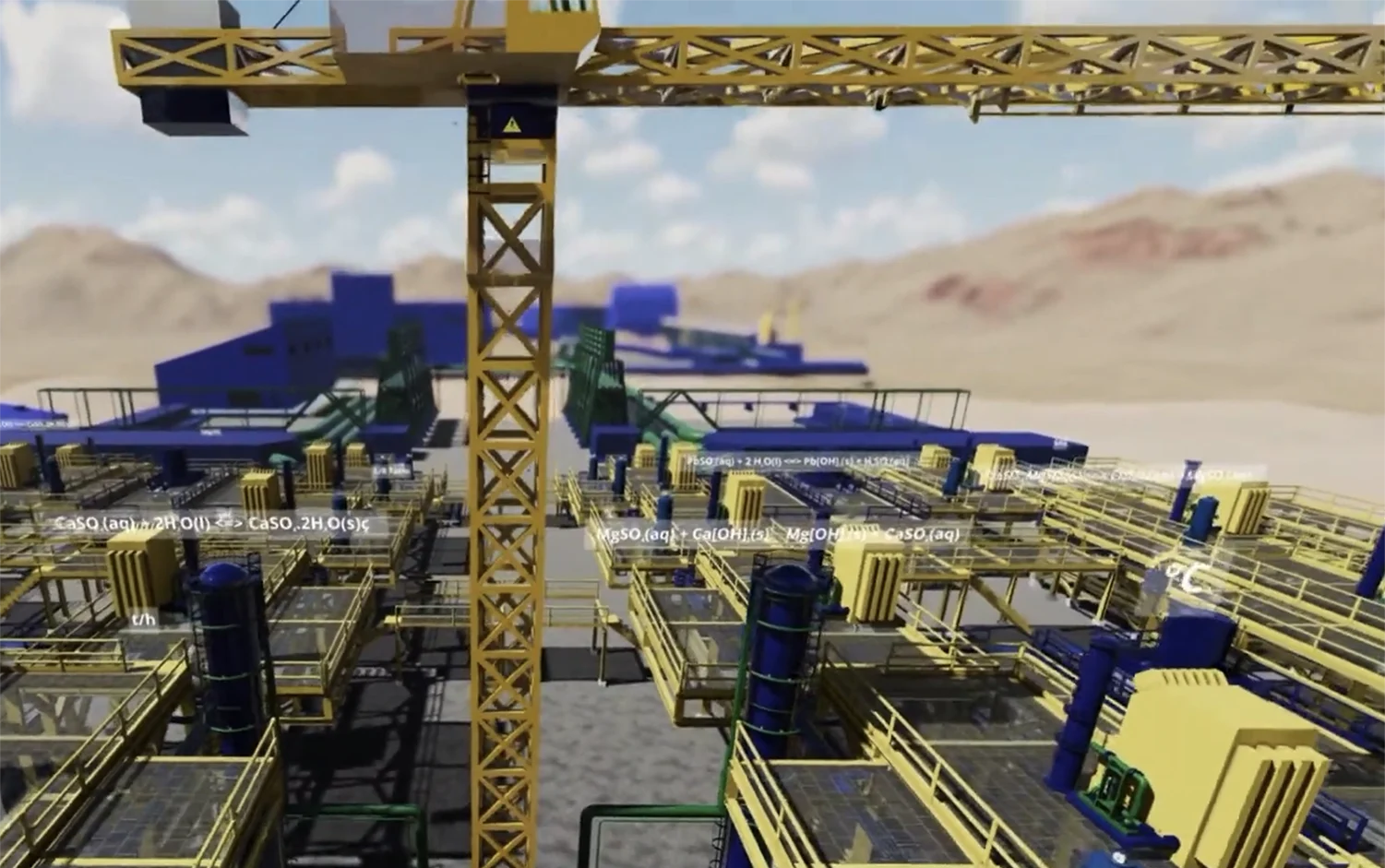

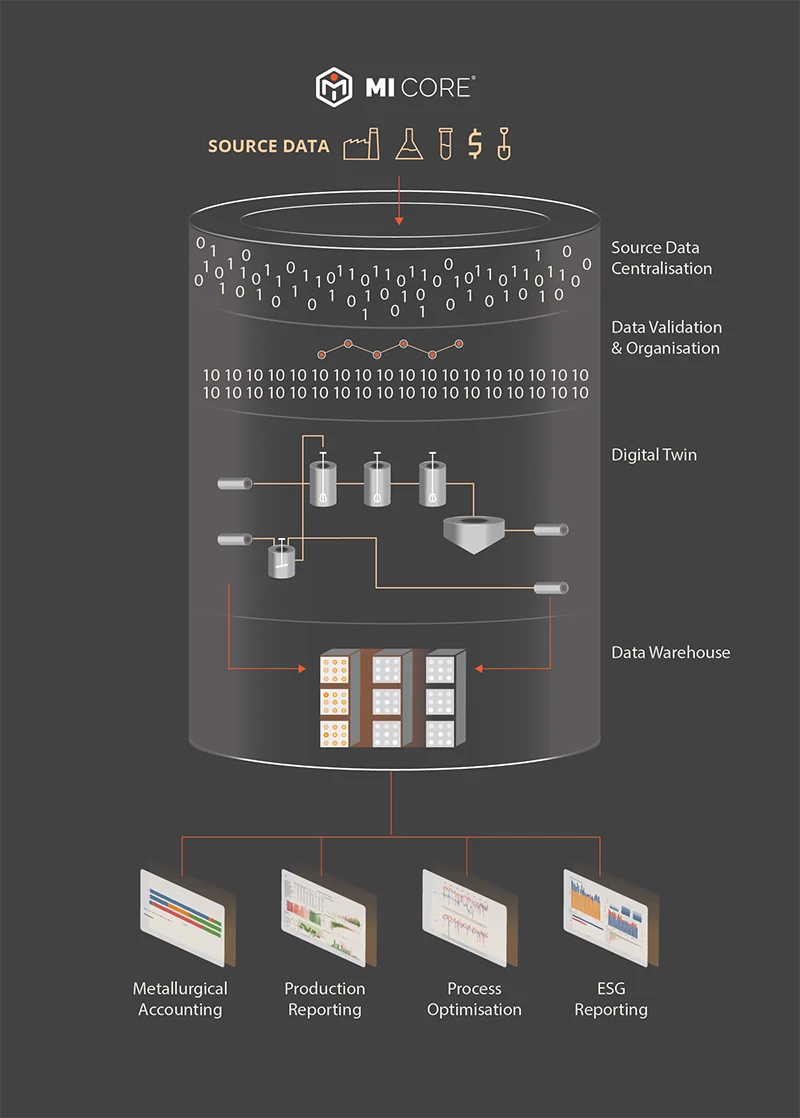

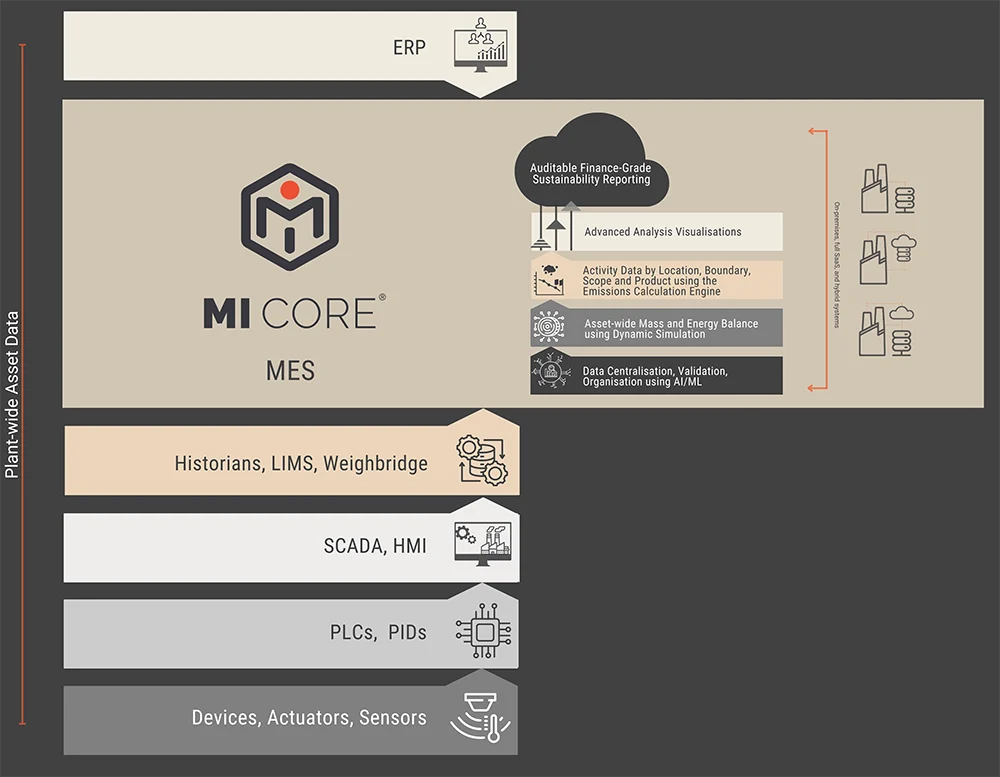

MI Core®, the foundation of the Metallurgical Intelligence® suite of solutions, is an established platform that centralises plant-wide data and dynamically simulates your processing operation as a digital twin. It performs a plant-wide mass and energy balance and delivers granular reports and deep analysis across sustainability indicators to comply with evolving global frameworks.

It’s becoming increasingly important for mining executives to deliver transparent and accurate sustainability reporting to their stakeholders, showing measurable improvement.

Yet, without the right data at hand, sustainability reporting can be very time consuming and complex, especially if you have plants that operate in multiple reporting jurisdictions. If the mineral processing organisation misrepresents reporting on this sensitive and critical topic for any reason, it could quite conceivably face huge financial and reputational risks. In fact, investors are increasingly demanding more transparent reporting.

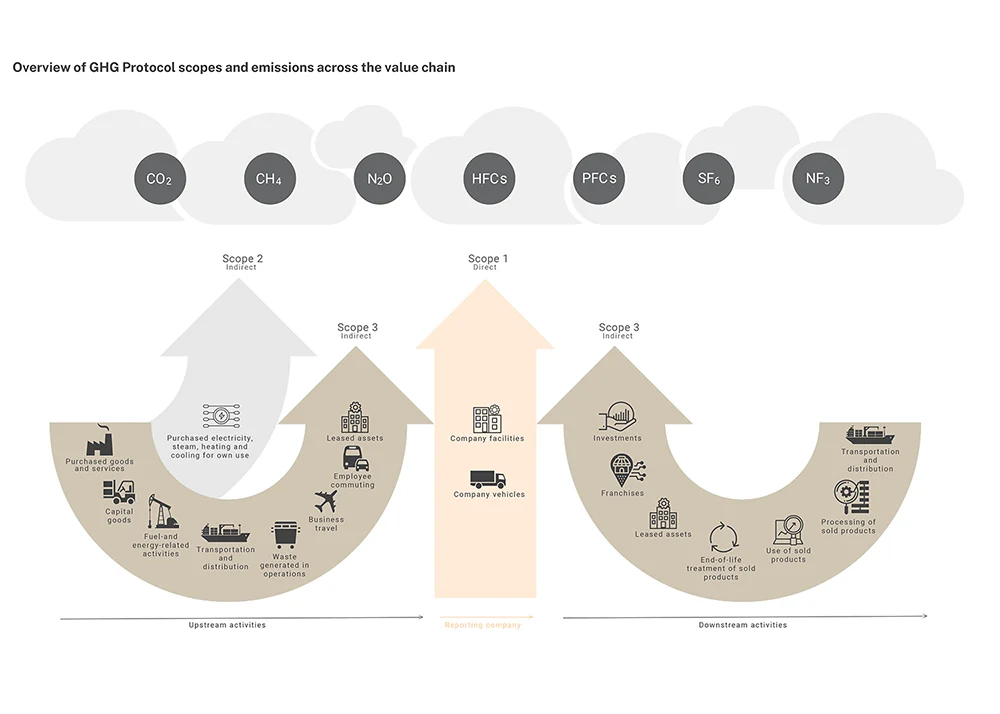

MI’s core functionality powers metallurgical accounting, process

optimisation and production reporting. On top of this, it has in-built

world-leading capabilities around auditable reporting for sustainability

indicators such as GHG emissions across Scopes 1, 2 and 3, water,

energy, air quality, waste, hazardous materials, pollutants and

nature-related risk factors. For example, it is ideally suited to Carbon Border Adjustment Mechanism (CBAM) reporting and compliance which impacts many global operations.

The award-winning platform gives mining organisations end-to-end transparency of their sustainability indicators (Scopes 1,2 & 3 and Climate & Nature) across their operations so they can comply with evolving global frameworks and reduce their emissions and environmental impact.

Available as on-premises, hybrid or a software-as-a-service (SaaS) solution, you can choose the licensing and delivery option that’s best for you.

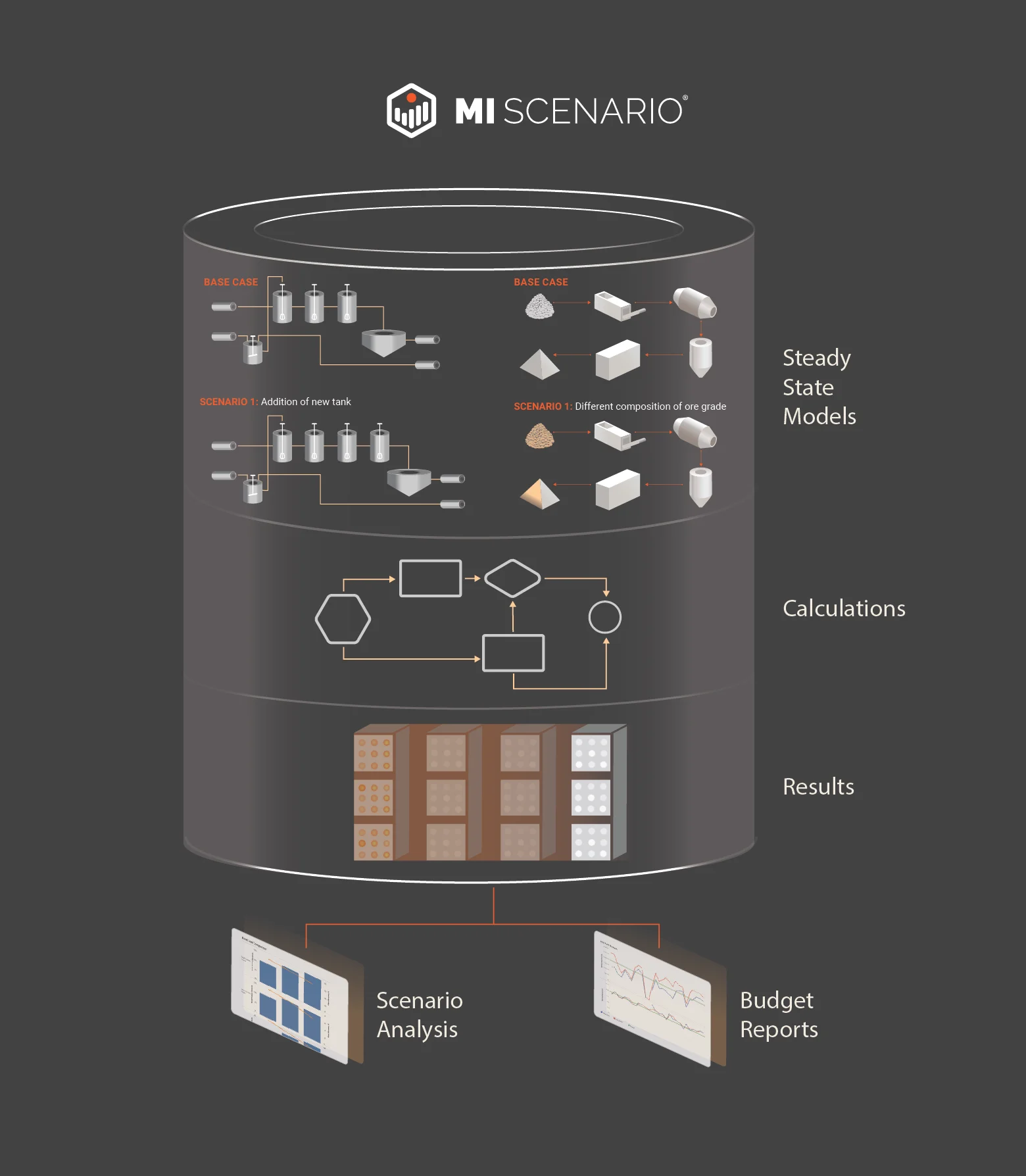

Complete the picture with MI Scenario®

As part of evolving global regulations, organisations will be required to include detailed dynamic scenario analysis as part of the sustainability reporting. By leveraging our steady-state plant simulation model MI Scenario®, an extension to MI Core®, you can set targets, budgets, forecasts and run what-if scenarios using data from your process digital twin, sourced from across your plant, to predict likely future processing outcomes and identify efficiencies.

Together, this technology supports the ESG initiatives of mining companies in four key areas: energy efficiency, yield improvement, greenhouse gas emissions and new green processes. Granular detail and advanced modelling provide minerals processing professionals with a reliable, trusted and straightforward way of planning, tracking and demonstrating reduced emissions, power and water consumption, and other climate and nature related indicators.

Together, they give you a very clear picture of your plant’s emissions, plus the powerful ability to test alternative scenarios and set accurate reduction targets.

Road-tested since 2010 in complex mining and minerals sites across 8 countries and in 4 languages, the Metallurgical Intelligence® suite is your proven fast-track solution to sustainability compliance and accurate reporting.

How does it work?

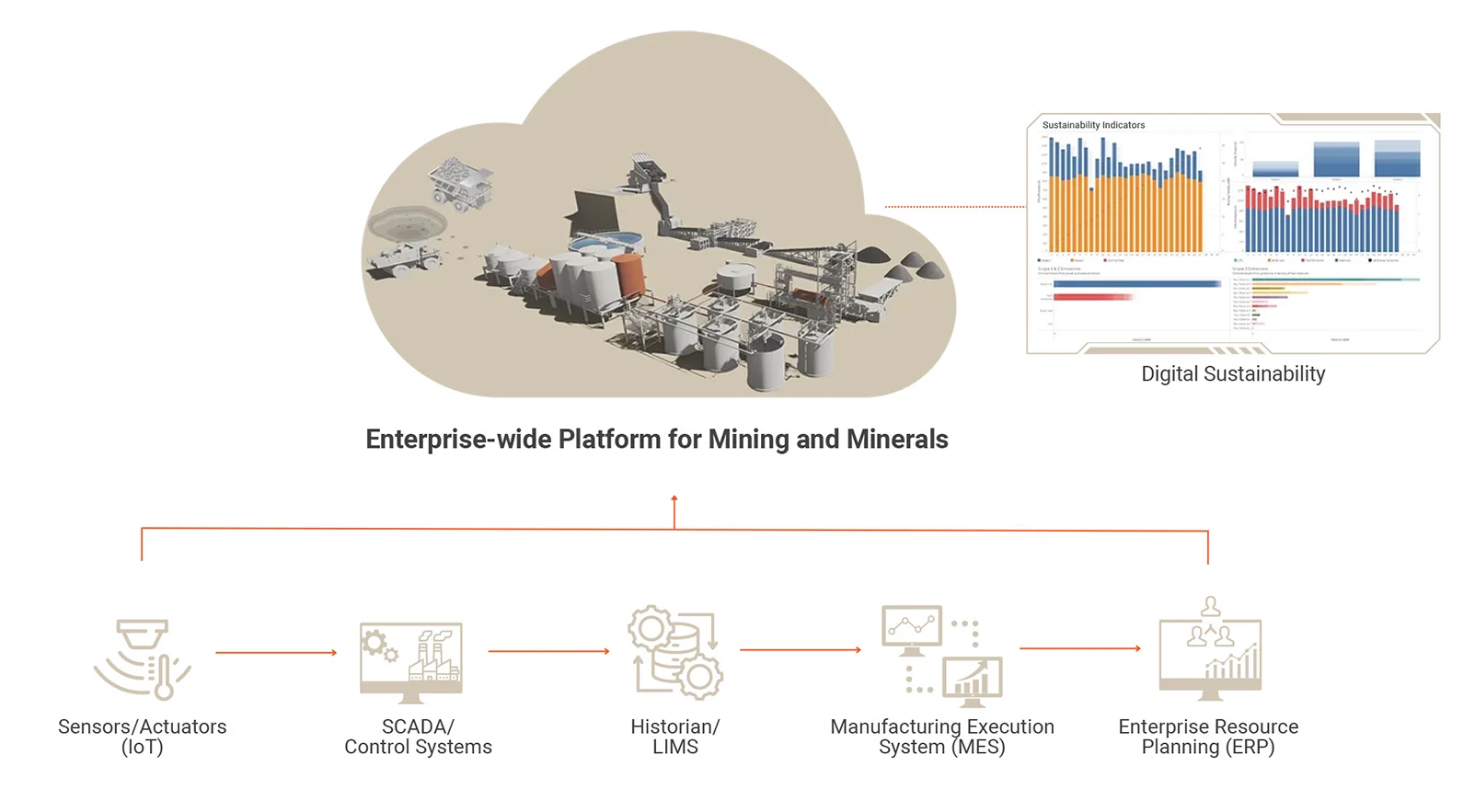

MI Core® integrates seamlessly with your existing systems and is customisable to your unique plant and processes. It automatically centralises huge volumes of data from multiple sources across your operation and supply chain, and uses machine learning to validate and organise the measured and corrected data.

Uniquely, MI Core® uses dynamic simulation to perform a plant-wide mass and energy balance to reconcile your delivery, consumption, inventory and production activity data. Using source data as inputs, the simulated data contextualises your measured activity data for completeness and accuracy.

This means your verified sustainability indicators are fully traceable, immutable and unalterable, and surpass any rigorous audit tests for complete assurance.

Enterprise-wide platform

Ever-tightening policies are coming into force

While new global sustainability regulations already target energy-intensive industries like mining, minerals, energy and other resources, this is only the beginning.

According to the World Bank, there were 68 direct carbon pricing instruments already operating in 46 national jurisdictions 2022, with more coming into force at pace.

In Australia, the Safeguard Mechanism is the Government’s policy for reducing emissions at Australia’s largest industrial facilities. It sets legislated limits (baselines) on the greenhouse gas emissions that will decline on a trajectory in line with achieving the national target of net zero by 2050. Combined with the reporting obligations under the National Greenhouse and Energy Reporting Act 2007, it requires Australia’s largest emitters to measure, report and manage their emissions at or below baselines set by the Clean Energy Regulator.

Legislated as part of the European Green Deal, the Carbon Border Adjustment Mechanism (CBAM) – also referred to as the carbon border tax – is a tariff applied to a range of carbon intensive products that are imported by the European Union (EU). Whether your organisation manufactures in the EU or is a non-EU-based supplier to these organisations, CBAM compliance requirements will apply to in-scope products from October 2023.

One solution for granular, finance-grade auditable reports

Designed to navigate more than 2,000 global reporting frameworks and over 1,424 separate ESG performance indicators, MI Core® is a uniquely flexible and comprehensive sustainability reporting solution for today, and the future.

- Track end-to-end sustainability indicators spanning Scopes 1, 2 & 3, and Climate & Nature

- Single source of centralised, validated, organised and integrated sustainability data

- Accurate plant-wide mass and energy balance customised to your exact process as a digital replica of your operations

- Contextualise your measured activity data using source data as inputs

- Analyse, track and report activity data right down to a product level

- Track and consolidate on-site and off-site renewable energy sources

- Capture and report on data directly related to the mining asset it has been implemented in, including integration with third party data

- Track, simulate, test, analyse and forecast scenarios

- Future-proof technology delivered in a scalable cloud-based SaaS platform

Reports spanning Scopes 1, 2 & 3, and Climate & Nature

Direct Emissions

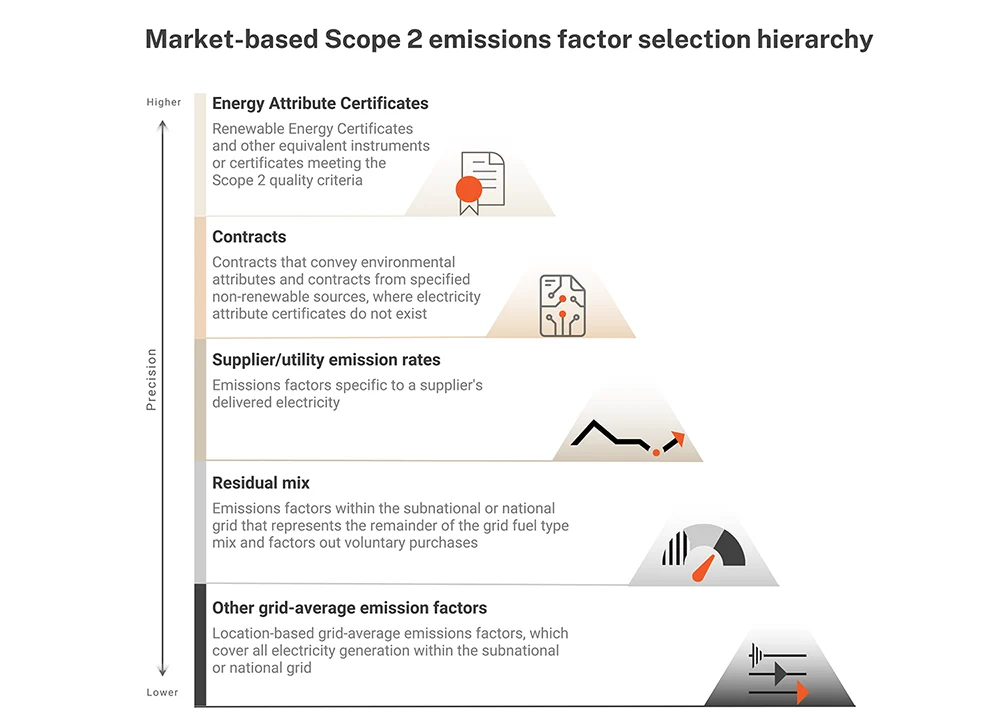

Electricity Indirect Emissions

Other Indirect Emissions

Direct Emissions

Source: Graphic adapted from the Greenhouse Gas Protocol (GHGP)

Electricity Indirect Emissions

Source: Graphic adapted from the GHG Protocol Scope 2 Guidance

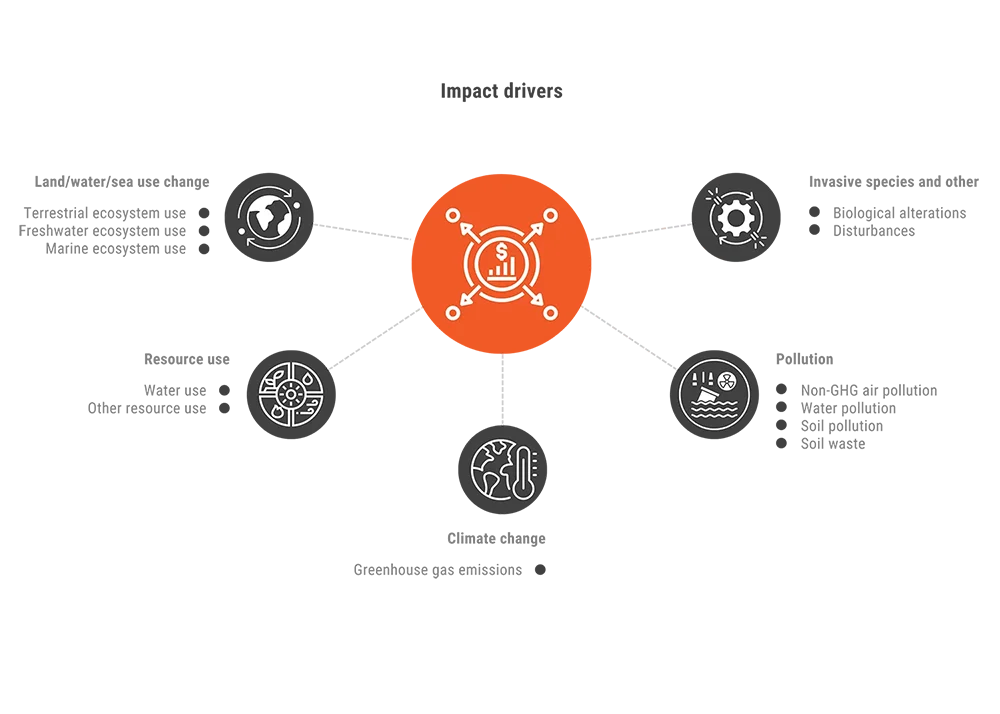

Other Indirect Emissions

Source: Graphic adapted from the Greenhouse Gas Protocol (GHGP)

Graphic adapted from the Task Force on Nature-related Financial Disclosures (TNFD) Annex Framework

Delivering real-world results

Digital tracking uncovers $US1.5M per year in unused power

From under reporting sulphuric acid emissions by 26% to paying millions for unused power over time, we look at three examples where our digital sustainability platform delivered tangible results.

Global compliance and less carbon tax for hydrometallurgical facility

Our solution helps this industrial leader in Africa meet tighter compliance regulations, track electricity use, minimise their carbon tax bill and deliver mandatory auditable reports.

Using data to reduce the carbon footprint of battery production

We empowered a battery producer to cut emissions and waste by measuring an accurate reporting baseline, setting targets and testing scenarios using steady-state simulation technology.