Metallurgical Scenario Analysis

Test scenarios and optimise plant performance with confidence

Enhance decision-making in your mineral processing plant with rigorous scenario testing. Discover ways to enhance productivity and profitability, reduce risk, and realise better ESG outcomes.

From geopolitics to environmental concerns, cost optimisation to mineral scarcity, the mining and minerals sector is under more pressure than ever to do more with less. Yet making changes to plant processes can carry big risks and materially impact business models.

Scenario testing presents an opportunity to use the massive volumes of data generated in a plant to explore ‘what if’ scenarios. From these insights, leaders can make more informed decisions about how to optimise outcomes. Leading minerals process plants are using scenario testing to solve for big issues like ESG reporting and greenhouse gas emissions, productivity, forecasting and cost control, as well as more granular metrics like reagent quantities, altered flowsheets and other production variables.

Predict the future using data from the past

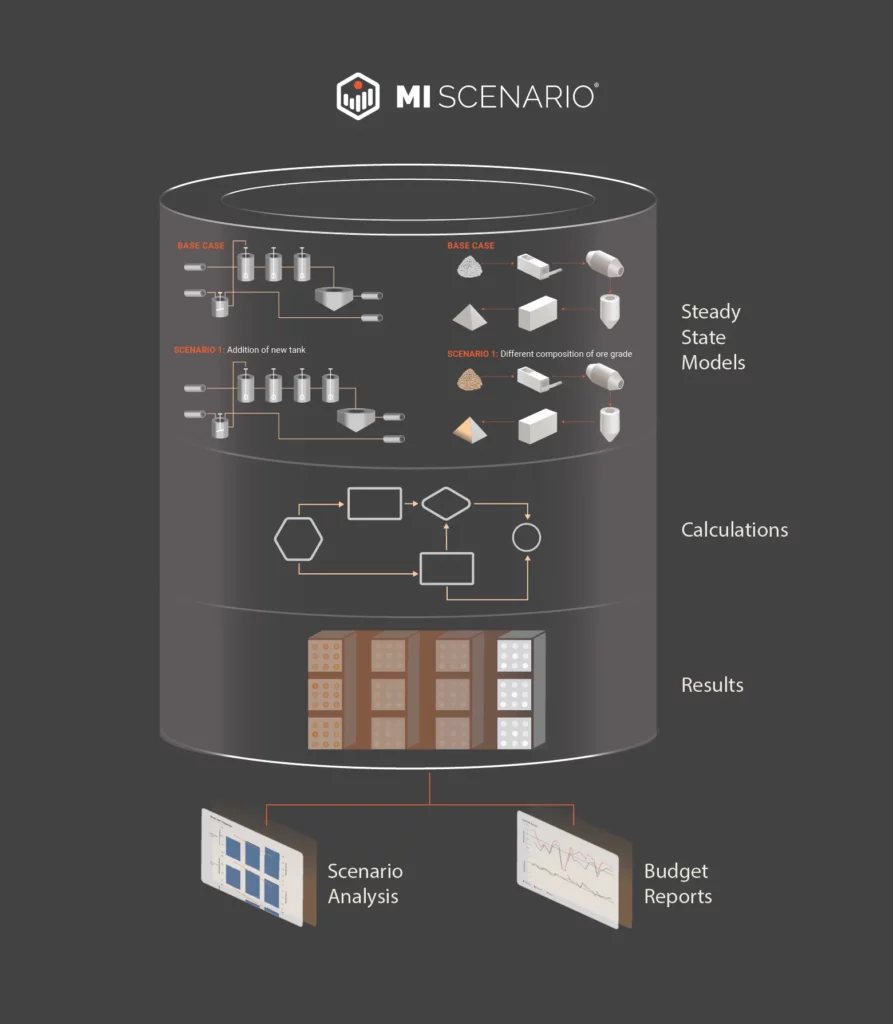

Use a steady-state simulation technology and adjust input values and/or flowsheets to test scenarios.Drive continual optimisation

By answering ‘what if’ questions with accuracy and confidence, decision-makers can take decisive action.Reduce emissions, waste and consumption

Test and evaluate scenarios to determine how specific changes in a range of variables will improve ESG outcomes.ESG remains the top risk and opportunity for mining and metals companies in 20231.

Scenario testing plays a key role in managing ESG

According to the global Task Force on Climate-related Financial Disclosures (TCFD), scenario analysis is a key tool to help companies understand and quantify the risks and uncertainties of different hypothetical futures.

When it comes to climate scenarios — which can be particularly complex given timescales, scientific models, and the multi-faceted nature of consequences — choosing the right scenario testing tool proves critical. You need a tool that can test scenarios to reduce Scope 1, 2 and 3 emissions; one that can test everything from the impact of replacing fossil fuels with biomass, to using recycled instead of virgin materials.

That’s where Metallurgical Intelligence comes in. Our proven, industry-leading scenario testing solution — MI Scenario® — enables powerful analysis and testing of an endless range of variables and scenarios, helping you optimise operations and hit your ESG targets with confidence.

Remove the guesswork with MI Scenario®

Scenario testing is all about answering ‘what if’ questions with absolute certainty. Questions like, what if we increase throughput? What if we add in another tank? What if we target a higher grade? What if a reactor goes offline or equipment fails? Or, if we made this change to our suppliers, could we reduce our greenhouse gas emissions?

MI Scenario® is an optional module in the award-winning MI Core® process digital twin solution from Metallurgical Systems. It uses a customised steady-state plant simulation model to predict the future for your plant by combining data from the past with known or expected upcoming changes in processing conditions. It can accurately determine potential outcomes to any modifications you propose — helping you make accurate, cost-effective and informed decisions about the way you run your plant.

By pairing our proven scenario testing solution with a process digital twin, process optimisation tool, or asset utilisation tool, you can further optimise plant performance.

Why MI Scenario® for scenario testing?

- Deep insights

Instead of using time as a dimension, steady-state simulation represents a fixed period — which means you can capture more detail and use more complex plant relationships to find answers to the big ‘what if’ questions. - Fully customised

Select a snapshot of historical data as the basis for a scenario, then generate any number of variations as separate cases. You can even customise the plant model to trial different flowsheets and new equipment. - Flexible and scalable

MI Scenario® has been adapted for every type of minerals processing technology, including concentrators, hydrometallurgy plants, smelters and refineries. Even the most detailed process parameters can be captured and reported. - Fully integrated

MI Scenario® uses real data from MI Core® as its primary input. You can transfer results from MI Scenario® back to MI Core® to use as budget or forecast data, and you can compare scenario results to real plant data to better understand performance and utilisation. - Accurate data

Check and cross-check the measured data coming from plant sources. Gain more visibility than ever before, as well as far greater flexibility to generate simulations with structured plant data. - Unlimited testing

There is no limit to the number of ‘what if’ scenarios you can run. Investigate process optimisation, plan budgets and forecast with unprecedented confidence, conduct stress tests or even trial plant configuration changes.

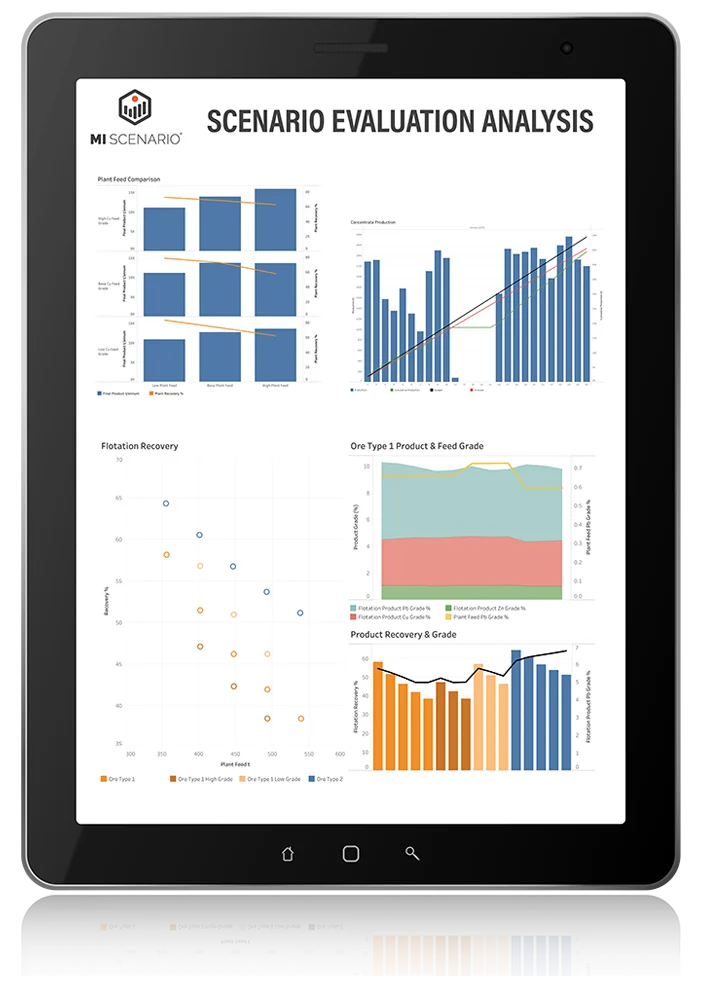

Access rich reporting and powerful dashboards

- Easily understand and plan for the effects of different scenarios.

- Customise the model to calculate and report on everything from production rates and product grade, to impurities and recovery.

- Plan for upcoming changes and adjust processing strategies to maximise recovery or production.

- Stay one step ahead of compliance and the surge in carbon tax policies.

Use scenario testing to achieve real results

MI Scenario® is proven to deliver actual improvements in mineral processing plant operations of up to:increased recovery

reduction in reagent usage