How to calculate battery carbon footprint declarations and achieve compliance using Product Carbon Footprinting (PCF) software.

Reference: thebatterypass.eu, Battery Passport Content Guidance – Executive Summary (page 30), December 2023

As the demand for batteries rises – driven by transport electrification, renewable energy storage and mobile devices – so does the need for sustainable battery production. For mining operations, there is a long-term opportunity to capitalise on this shift by suppling the battery minerals, particularly cobalt, nickel and lithium.

The European Union’s (EU) Batteries Regulation requires manufacturers, producers, importers and distributors to calculate and declare each battery’s carbon footprint via a Battery Passport that tracks its environmental performance throughout its lifecycle.

This poses significant challenges for manufacturers who must navigate complex data collection, calculation and reporting processes. Digital tools, including Product Carbon Footprinting (PCF) software, are essential to manage compliance effectively.

Drawing on over 10 years of experience in process engineering, data-led software and ESG reporting in the resources sector globally, this guide explains the EU Batteries Regulation, how to prepare and the technology solutions available.

Contents

- EU Battery Regulation: Product Carbon Footprint (PCF) Requirements

- Carbon footprint and the Battery Passport

- Carbon footprint implementation plan

- How to calculate the carbon footprint

- Secondary legislation following the EU Batteries Regulation

- How to use Metallurgical Intelligence® to track company and product-specific data

- Take control of your EU Batteries Regulation compliance

The mining opportunity: Rising demand for battery minerals

While it is a volatile market, the rising long-term global demand for battery minerals – particularly cobalt, nickel, and lithium – is being driven by factors such as the adoption of renewable energy technologies, electrification of transportation, energy storage needs and portable electronic devices.

Despite recent price volatility for some battery metals, long term demand outlook remains strong. This presents significant opportunities and challenges for the mining and minerals sector.

To capitalise on this opportunity in a fluctuating and competitive market, minerals-processing plants will need to implement innovative solutions to optimise recovery rates and operating efficiencies to produce high-grade products while minimising waste and costs.

As emphasis on environmental, social, and governance (ESG) considerations intensifies, efficient processes and emissions tracking down to a product level become essential for tracking, managing, and reporting on sustainability goals.

By embracing these strategies, mining and minerals operations can capture their slice of this rapidly evolving battery market while contributing to a more sustainable future.

What is the EU Batteries Regulation?

The EU Batteries Regulation, which took effect on 17 August 2023, is a landmark legislation that replaces the 2006 Batteries Directive, which previously regulated the sustainability of batteries in the EU.

Spanning the entire lifecycle of battery production, it aims to reduce the environmental footprint of batteries, protect human health, and promote sustainable battery production, collection and recycling practices.

The Regulation applies to all EU Member States and covers all batteries sold in the EU market (see scope below). It extends to manufacturers, producers, importers and distributors, regardless of battery origin or raw material source.

Key provisions:

- Ensures batteries have a low carbon footprint, minimal harmful substances and reduced reliance on non-EU raw materials

- Promotes responsible supply chain management, focusing on critical materials like cobalt, lithium, nickel and natural graphite

- Introduces gradual targets for recycling efficiency, material recovery and recycled content from 2025 onwards

- Mandates high levels of recovery for critical raw materials, supporting a circular economy and strategic autonomy

The EU Batteries Regulation sets a new benchmark for sustainable battery management, aligning with the European Green Deal’s ambitions for an increasingly circular economy.

By adopting a comprehensive lifecycle approach, this legislation paves the way for a more environmentally responsible and resource-efficient battery value chain.

What is the scope of the EU Batteries Regulation?

The Regulation establishes a comprehensive framework governing the placement and service of batteries within the EU. It applies to batteries manufactured within the EU and those imported into the EU, ensuring a level playing field for all economic operators.

Its scope covers:

- Sustainability and environmental requirements

- Safety standards

- Labelling and marking guidelines

- Information provision obligations

The Regulation outlines minimum requirements for:

- Extended producer responsibility

- Waste battery collection and treatment

- Reporting obligations

- Battery due diligence for economic operators

- Green public procurement for battery purchases

It applies to all battery categories, regardless of their shape, volume, weight, design, material composition chemistry, use or purpose, and includes batteries integrated into other products.

The Regulation differentiates between various battery types, with distinct rules applying to each category, including:

- Portable batteries

- SLI (Starting, Lighting and Ignition) batteries

- LMT (Light Means of Transport) batteries

- Electric Vehicle (EV) batteries

- Industrial batteries

Who is impacted by the EU Batteries Regulation?

Any entity playing a role in manufacturing, distributing or deploying batteries within the EU must comply with the Regulation’s requirements.

The rules apply to a broad range of entities involved in the battery value chain, collectively called ‘economic operators’. This term encompasses:

- Manufacturers

- Authorised representatives

- Importers

- Distributors

- Fulfillment service providers

- Anyone responsible for producing batteries, preparing them for re-use, repurposing, or remanufacturing, selling them (including online) and putting batteries into service.

Additionally, the Regulation applies to public authorities and government entities procuring batteries or products containing batteries, which must comply with specific requirements for green public procurement.

When does the EU Batteries Regulation take effect?

The EU Batteries Regulation will be phased in over several years, with the implementation including the following key milestones:

- February 2024: Initial provisions take effect

- August 2024: Economic operators’ obligations (excluding due diligence policies and end-of-life management) take effect, and conformity assessment rules start to apply

- August 2025: End-of-life management rules take effect

- February 2027: Removability and replaceability requirements for portable and Light Means of Transport (LMT) batteries become mandatory

Note: The Regulation’s implementation follows a gradual approach, with varying timelines and rules for different battery categories.

Overview of EU Batteries Regulation Requirements

Sourced from the Battery Passport Content Guidance published by Battery Pass, the following graph provides a high-level summary of the key requirements of the EU Batteries Regulation, categorised by lifecycle stage and requirement type.

This visual overview covers various aspects of the battery lifecycle, from material sourcing and production to end-of-life management, and introduces new requirements for substance restriction, recycled content, due diligence policies and more.

Regulation Categories |

Exemplary requirements |

Lifecycle Stages |

||

|---|---|---|---|---|

| Material sourcing & production | Use phase | End of life | ||

| Restriction of substances | Mercury, cadmium, lead restrictions – delegated acts potentially extending the list | |||

| Recycled content | Min. levels of recovered cobalt (16%), lead (85%), lithium (6%), and nickel (6%), increasing over time | |||

| Due diligence policies | Implementation of a due diligence policy, incl. traceability or chain of custody system | |||

| Green public procurement | Criteria for sustainable procurement procedures for battery to be established | |||

| Labelling and marking | List of general information on battery labels determined; QR Code required | |||

| Safety Parameters | Stationary energy storage systems requiring technical documentation on safety | |||

| Removability, replaceability | Portable batteries must be easily removable and replaceable by consumers | |||

| Performance, durability | Minimum performance & durability requirements for batteries will be determined | |||

| State of Health (SoH), expected lifetime | Up-to-date data in the BMS to determine SoH and expected lifetime | |||

| Carbon footprint | Carbon footprint reporting required for the first time and for each model per manufacturing plant | |||

| Waste battery management | Collection targets as well as min. recycling efficiencies and levels of recovered Co, Cu, Pb, Li, Ni | |||

| Improved data availability | An electronic record of a battery (battery passport) with key static and dynamic data | |||

Reference: thebatterypass.eu, Battery Passport Content Guidance – Executive Summary (page 14), December 2023

Building on this high-level overview of the EU Batteries Regulation requirements, the following sections delve deeper into specific categories.

Following the same structure as the legislation, these sections further explain and analyse selected provisions, offering insights into their implications and requirements.

1. Sustainability and safety

Restrictions on hazardous substances:

The Regulation sets limits on mercury, cadmium and lead content in various battery categories to minimise environmental harm.

Carbon footprint declarations for electric vehicle (EV) batteries, rechargeable industrial batteries and LMT batteries:

Manufacturers of EV batteries, rechargeable industrial batteries with a capacity greater than 2kWh and Light Means of Transport (LMT) batteries must declare the carbon footprint of each model per manufacturing plant.

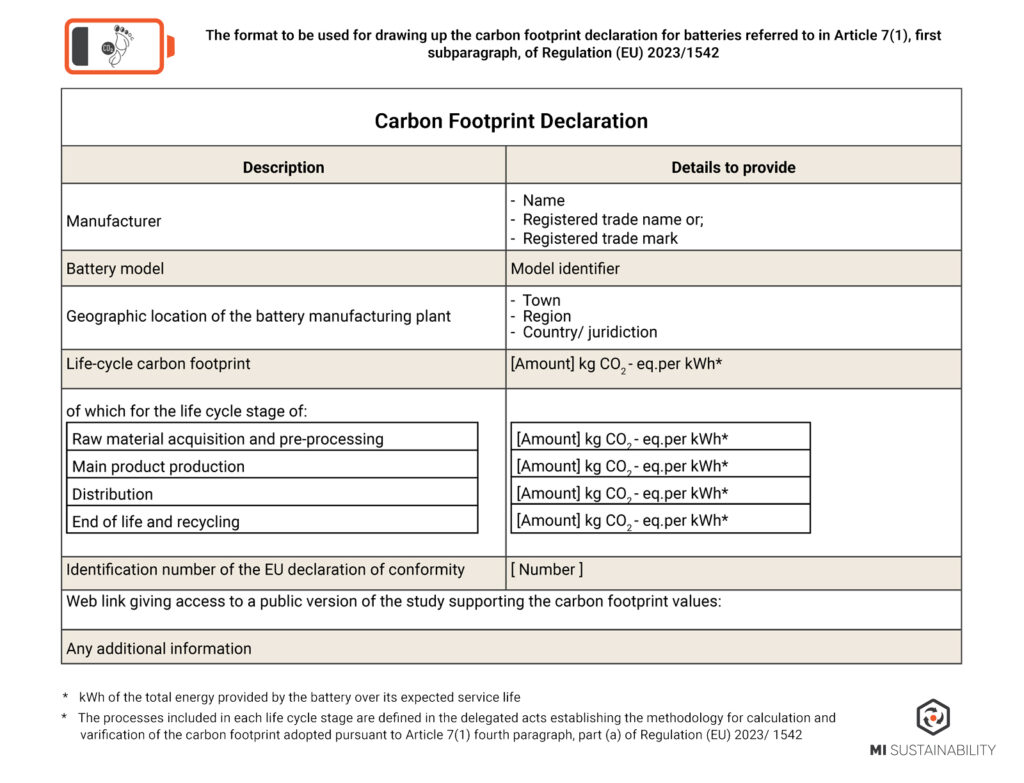

The draft implementing act feedback, which closed in May 2024, outlines the format of the carbon footprint declaration that companies need to use when declaring the carbon footprint of their batteries as below:

The key milestones for carbon footprint declarations outlined in the regulations are:

- February 2025: Electric Vehicle (EV) batteries

- February 2026: Rechargeable industrial batteries (excluding those with exclusively external storage)

- August 2028: Light Means of Transport (LMT) batteries

- August 2030: Rechargeable industrial batteries with exclusively external storage

The carbon footprint declaration is for the entire lifecycle of the battery, only excluding the use phase of the battery which is out of scope of the Regulation.

>> Calculating the carbon footprint of EV batteries

The European Commission is developing a methodology for calculating and verifying the carbon footprint of EV batteries as part of the EU Battery Regulation. This is the first step towards a standard approach for all battery types, with separate delegated acts to be developed for Industrial and LMT batteries.

The methodology will be outlined in a delegated regulation, with the EV Battery Act being the first to be released for consultation (Deadline: Feb 2025).

The methodology is based on a report by the Joint Research Centre (JRC) and stakeholder input and follows the Product Environmental Footprint (PEF) method set out in Commission Recommendation (EU) 2021/22793. The feedback period for this draft delegated Regulation closed on 28 May 2024.

>> Verification of carbon footprint methodology

The Regulation required the Commission to establish a methodology for accurately verifying the carbon footprint. This methodology will:

- Specify the minimum requirements for verification by notified bodies

- Identify areas that require onsite assessments by notified bodies, their subsidiaries or subcontractors

- Outline the necessary details for the study supporting the carbon footprint, which manufacturers must prepare

- Ensure that notified bodies and market surveillance authorities receive the information required to verify compliance

Recycled content requirements in batteries:

Article 8 of the Regulation requires industrial batteries over 2kWh, EV batteries and SLI batteries containing the active materials cobalt, lead, lithium or nickel to document the percentage share of recycled cobalt, lithium or nickel that is present in their active materials from August 2028.

Minimum recycled content targets have been set for these battery categories, with initial targets effective August 2031 and more stringent targets effective August 2036.

Additionally, Chapter 2 of the Regulation outlines performance requirements, removability and replaceability standards for certain batteries and safety regulations for stationary battery energy storage.

Performance and durability requirements:

Certain batteries, including rechargeable industrial batteries over 2kWh, LMT batteries and EV batteries, must be accompanied by a document specifying their durability and electrochemical performance parameters. When placed on the market, these batteries must also meet the minimum criteria for durability and electrochemical performance parameters set out in the Commission’s delegated act.

Removability and replaceability of portable and LMT batteries:

Portable and LMT batteries must be designed to be removable from equipment and replaceable by consumers. Additionally, manufacturers must provide instructions and safety information on these batteries’ use, removal and replacement, which must be permanently available on a publicly accessible website.

Safety requirements for stationary battery energy storage systems:

Stationary battery energy storage systems placed on the market or put into service must be accompanied by technical documentation demonstrating that they comply with the safety parameters set out by the legislation and have successfully passed safety testing.

2. Battery labelling, marking and information

Chapter 3 of the EU Batteries Regulation covers the labelling and marking of batteries, such as some batteries containing cadmium and lead, and information regarding the health and expected lifetime of some batteries.

For example, all categories of batteries are to be labelled according to Annex VI Part A:

ANNEX V1: LABELLING, MARKING AND INFORMATION REQUIREMENTS

Part A: General information on batteries

Information on the label of a battery shall comprise the following information regarding the battery:

- information identifying the manufacturer in accordance with Article 38(7);

- the battery category and information identifying the battery in accordance with Article 38(6);

- the place of manufacture (geographical location of a battery manufacturing plant);

- the date of manufacture (month and year);

- the weight;

- the capacity;

- the chemistry;

- the hazardous substances present in the battery, other than mercury, cadmium or lead;

- usable extinguishing agent;

- critical raw materials present in the battery in a concentration of more than 0,1% weight by weight.

Batteries are to be labelled with specific markings, including a symbol for separate collection and warnings for cadmium and lead content above certain thresholds. A QR code and physical label with mandatory information, varying by battery category, are also required.

Additionally, certain battery types (LMT, Industrial, EV) must have a Battery Management System (BMS) that provides real-time data on the battery’s state of health and expected lifetime.

3. EU Declaration of Conformity and CE Marking

As outlined in Chapter IV of the legislation, manufacturers must draw up the EU Declaration of Conformity, which is a document that certifies a battery’s compliance with relevant EU regulations. It includes:

- Battery model and identification

- Manufacturer’s name and address

- Statement of manufacturer’s responsibility

- Description of the battery for traceability

- Declaration of conformity with EU harmonisation legislation

- References to harmonised standards or technical specifications

- Details of the notified body’s intervention and certification

- Additional information and signature block

Additionally, the manufacturer must affix the CE (Conformité Européenne) marking to each battery type, indicating conformity with EU requirements. The CE marking must be:

- Visible, legible and indelible on the battery or its packaging/documents

- Accompanied by the identification number of the notified body, as required under Annex VIII

- Affixed before the battery is placed on the market or put into service

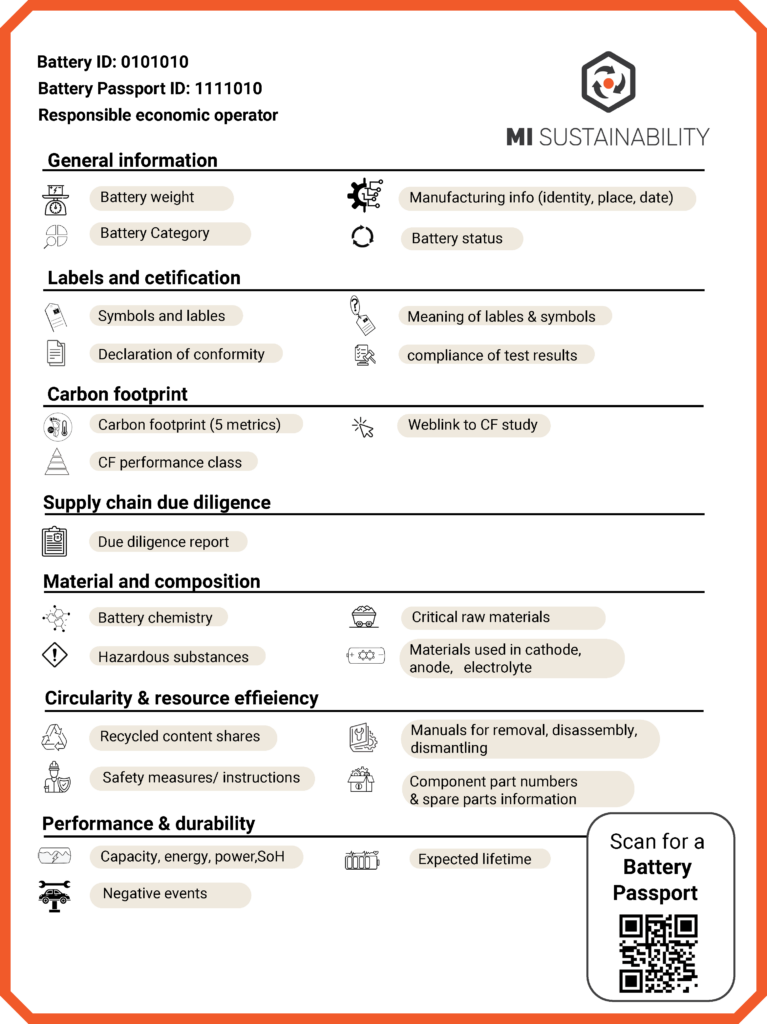

4. Battery Passport requirements

From February 2027, the following batteries must have an electronic record called a Battery Passport:

- Light Means of Transport (LMT) batteries

- Industrial batteries (>2kWh)

- Electric Vehicle (EV) batteries

The Battery Passport is to contain a range of technical information about the battery model and specific details on the individual battery, including material composition, rated capacity and carbon footprint information. It must be accessible through an easily legible QR code.

For second-life batteries, a new passport must be created and linked to the original battery’s passport. The passport will be deactivated once the battery is recycled.

The information in the Battery Passport will have varying levels of accessibility, including:

- Publicly accessible information

- Information for those with a legitimate interest

- Information for the Commission, notified bodies and market surveillance authorities

- Information accessible only to persons with a legitimate interest (as outlined in Annex XIII of the Battery Regulation)

An implementing act (yet to come) will specify the access rights for each category of information.

5. Due diligence for economic operators

Economic operators with a net turnover of €40 million or more (in the preceding financial year), or those part of a group exceeding this limit, must comply with a range of due diligence obligations, including:

- Adopt policies concerning raw materials (such as cobalt, natural graphite lithium, nickel), social and environmental risk categories such as environment, climate and human health, human rights and community life.

- Due diligence policies must be verified by a notified body, which provides the economic operator with an audit report.

- Establish and adopt an economic operator’s management system.

- Risk management – identify and assess risks and design and implement a strategy to respond to identified risks.

- Third-party verifications of battery due diligence policies by a notified body: the notified body shall issue a verification report and approval decision.

- Maintain detailed records and disclose information on battery due diligence policies to Member States’ market surveillance authorities or national authorities upon request, including verification reports, approval decisions, audit reports and evidence of compliance.

Note: These obligations do not apply to economic operators with a net turnover of less than €40 million in the preceding financial year unless part of a group exceeding this limit.

6. End-of-life provisions for waste batteries

The Batteries Regulation aims to maximise separate collection and efficient and responsible recycling of batteries at their end-of-life stage, promoting recycling and reducing waste.

The following key requirements apply:

- Registration: Battery producers must register with the National Register of Producers.

- Extended producer responsibility: Battery producers and economic operators placing second-life batteries on the market are subject to extended producer responsibility.

- Financing: Battery producers must cover the costs of collecting, treating and recycling all collected batteries.

- Collective systems: Member States may require the establishment of collective systems (producer responsibility organisations).

- Collection targets: Increased and specific targets for portable battery and Light Means of Transport (LMT) battery waste have been set.

- Distributor obligations: Distributors must take back waste batteries from end-users free of charge and without requiring the purchase of a new battery.

- End-User obligations: End-users must discard waste batteries separately from other waste streams, including mixed municipal waste.

- Additional obligations: Take-back obligations, targets for recycling efficiency, material recovery, and reporting to authorities also apply.

EU Battery Regulation: Product Carbon Footprint (PCF) Requirements

A vital component of the EU Batteries Regulation, the PCF requires manufacturers to calculate and declare the carbon footprint of their batteries.

Article 7 of the regulations mandates a standardised method for calculating and reporting the carbon footprint for each battery model and manufacturing plant, making the information publicly available through a Battery Passport. It covers rechargeable industrial batteries above 2 kWh, LMT and EV batteries.

The carbon footprint declaration must be made for each battery model and manufacturing plant, including:

- Carbon footprint calculated as kg CO2e per kWh of total energy provided over the battery’s expected service life

- Differentiated per lifecycle stage (as described in Annex II, point 4)

As published in Battery Carbon Footprint by Battery Pass, the calculation methodology must:

- Build on essential elements as outlined in Annex II

- Comply with the European Commission’s Product Environmental Footprint (PEF) method and relevant Product Environmental Footprint Category Rules (PEFCRs)

- Reflect international agreements and technical/scientific progress in lifecycle assessment

- Use company-specific activity data and product environmental-compliant secondary datasets

- The carbon footprint must be calculated and reported per lifecycle stage

Regulatory requirements

The Battery Regulation makes carbon footprint calculation mandatory at placement on the market in the EU. The methodology follows the Battery Regulation in the form of a Delegated Act. Economic operators must declare the carbon footprint for each battery model per manufacturing plant, making the results publicly available via the battery passport.

Importance of accurate PCF

In its Battery Passport Content Guidance, Battery Pass emphasises that a transparent and consistent PCF calculation methodology is crucial for informed decision-making and achieving lifecycle decarbonisation. Guidance is needed for company-specific PCF reporting, and the Battery Regulation addresses this by making PCF calculation mandatory.

Carbon footprint and the Battery Passport

As per Annex XIII, Part 1(c) of the Battery Regulation, the following carbon footprint reporting requirements and data must be disclosed publicly through the Battery Passport:

- Declared carbon footprint

- Share of battery carbon footprint per lifecycle stage

- Carbon footprint performance class

- Web link to public carbon footprint study

- Administrative information about the manufacturer

- Information about the geographic location of the battery manufacturing facility

- Information about the battery model for which the declaration applies

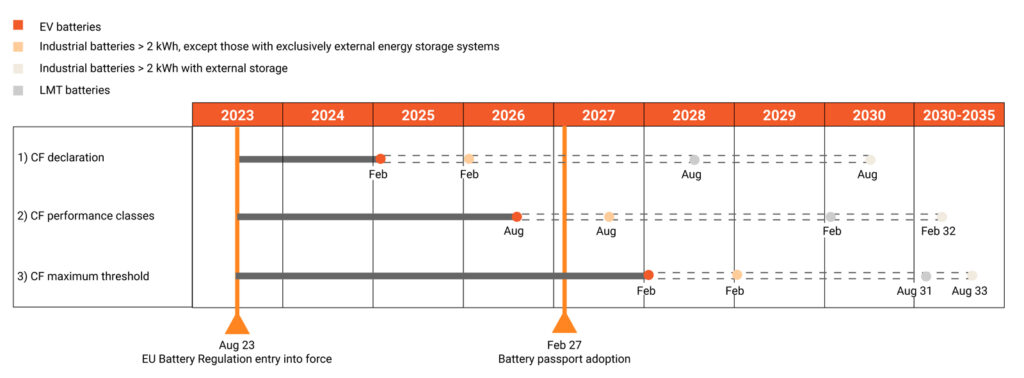

Carbon footprint implementation plan

The implementation of carbon footprint requirements for batteries involves three key steps:

- Declare carbon footprint: Manufacturers must declare the carbon footprint of their batteries.

- Assign performance class: Batteries will be assigned a performance class based on their carbon footprint.

- Set maximum thresholds: Maximum carbon footprint thresholds will be set for batteries.

Affected battery categories that require PCF calculations are:

- Electric Vehicle (EV) batteries

- Industrial batteries > 2 kWh (except those with exclusively external energy storage systems)

- Industrial batteries > 2 kWh with external storage

- Light Means of Transport (LMT) batteries

Implementation timeline:

- EV Batteries:

- February 2025: Declare carbon footprint

- August 2026: Assign performance class

- February 2028: Set maximum threshold

- Other battery categories: Later deadlines apply, TBC

- Battery Passport: Mandatory adoption starts February 2027

Reference: thebatterypass.eu, Battery Passport Content Guidance – Executive Summary (page 34), December 2023

How to calculate the carbon footprint

The delegated acts for each battery category will establish the methodology for calculating and verifying the carbon footprint, building on the components listed in Annex II of the EU Batteries Regulation.

This methodology must comply with the Commission’s Product Environmental Footprint (PEF) method and relevant Product Environmental Footprint Category Rules (PEFCRs). It must also align with international agreements and technical progress in lifecycle assessment.

The calculation of the lifecycle carbon footprint includes:

- Raw materials and components (bill of materials)

- Auxiliary materials

- Energy used in a manufacturing plant to produce a specific battery model

Electronic components such as battery management units, safety units and cathode materials must also be accurately identified, as they can significantly contribute to the battery’s carbon footprint.

Functional Unit:

The functional unit is defined as one kilowatt-hour (kWh) of the total energy provided by the battery system over its service life. This is calculated by multiplying the number of cycles by the amount of energy delivered per cycle.

Note: There are exceptions for backup batteries designed to ensure power continuity, as outlined in Appendix II of the Regulation.

Reference Flow:

The reference flow is the weight of the battery required to deliver a specific amount of energy, measured in kilograms of battery per kWh of total energy delivered over its service life. All quantitative input and output data collected by the manufacturer to calculate the carbon footprint must be related to the reference flow.

System boundary

The system boundary defines the lifecycle stages, processes, and activity data to be included in the carbon footprint calculation, as outlined in Annex II Part 4 of the Regulation and summarised below:

| Lifecycle stage | Processes involved | Activity data |

| Raw material acquisition and pre-processing | Includes mining and other relevant sourcing, pre-processing and transport of active materials, up to the manufacturing of battery cells and battery components (active materials, separator, electrolyte, casings, active and passive battery components) and electric or electronic components | Primary activity data voluntary Secondary data may be used |

| Main product production | Assembly of battery cells and assembly of batteries with the battery cells and the electric or electronic components | Primary activity data mandatory Secondary data must NOT be used |

| Distribution | Transport to the point of sale | Primary activity data voluntary Secondary data may be used |

| End of life and recycling | Collection, dismantling and recycling | Primary activity data voluntary Secondary data may be used |

The following processes are excluded from the system boundary:

- Manufacturing of equipment for battery assembly or recycling

- Battery assembly process using original equipment manufacturer (OEM) systems components

- The use phase of the battery is excluded from the calculation of the lifecycle carbon footprint

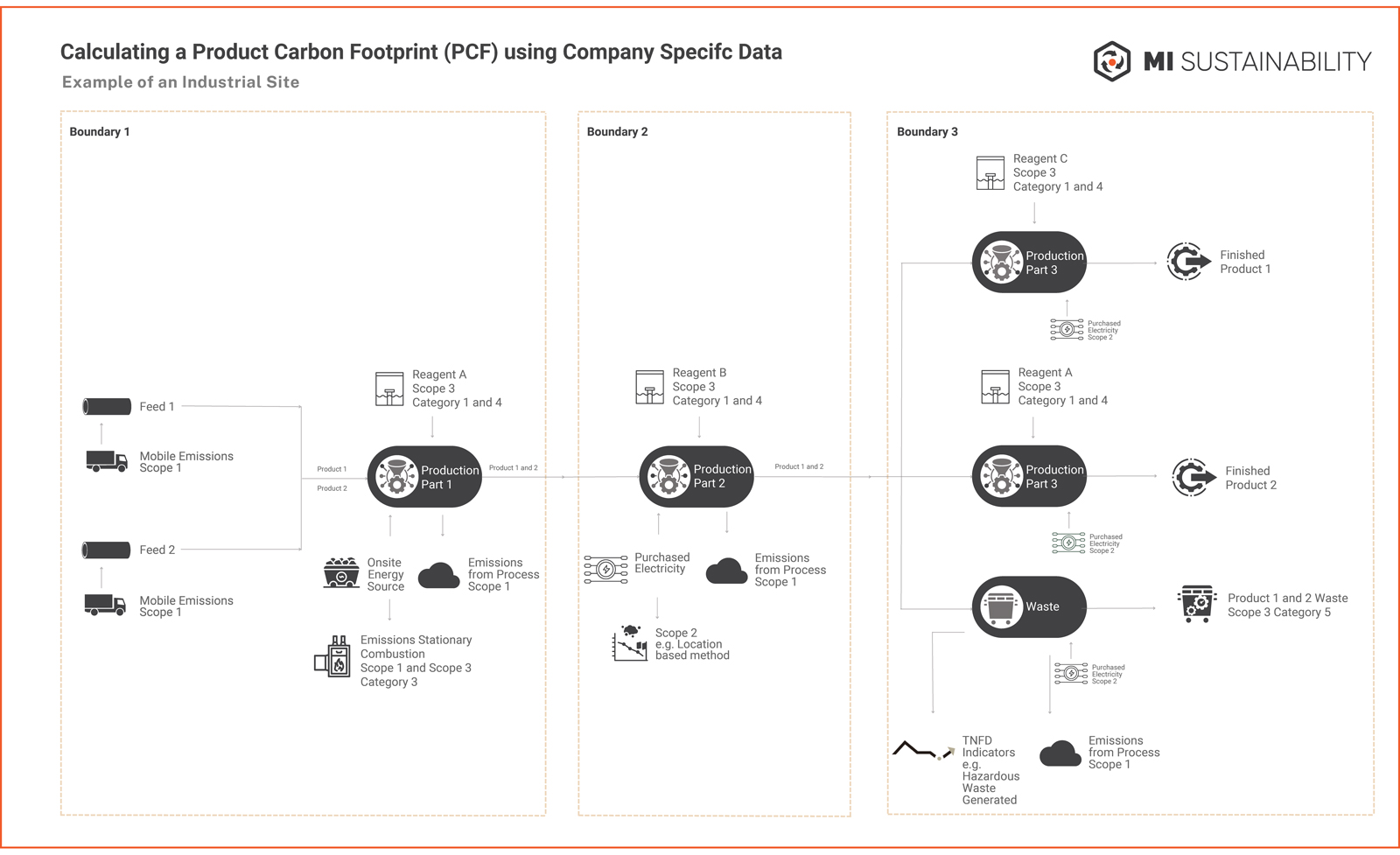

Company-specific and secondary datasets

The use of company-specific data to calculate the carbon footprint is limited to the process and component analysis of battery-specific parts. Primary data is required for the Main Product Production lifecycle stage, while secondary data may be used for other lifecycle stages.

All activity data related to the battery’s anode, cathode, electrolyte, separator and cell casing must refer to a specific battery model in a specific production plant, and no default data is allowed.

Battery-specific data is combined with Product Environmental Footprint (PEF) compliant secondary datasets. The carbon footprint declaration is specific to a battery model and a production facility, so sampling data from another production facility producing the same battery model is not permitted.

If the bill of materials or energy mix used to produce the battery changes, the carbon footprint for that battery model must be recalculated.

Carbon footprint impact assessment

The carbon footprint of batteries will be calculated using the Lifecycle Assessment (LCA) method recommended in the 2019 JRC Technical Report. As outlined in Annex II of the Regulation, this includes relying on the latest version of the Commission Product Environmental Footprint (PEF) method and reflecting technical and scientific progress in lifecycle assessment.

The European Commission developed a methodology for calculating and verifying the carbon footprint of various battery categories, starting with electric vehicle batteries. A draft delegated regulation was published in May 2024, drawing on a JRC Technical Report incorporating stakeholder input from workshops and consultations. The expert group on waste, comprising business and civil society representatives, also provided feedback on the report.

The carbon footprint results are to be presented as characterised results, using characterisation factors such as global warming potential, available on the European Platform on Lifecycle Assessment (LCA).

Offsets

Offsets are not to be included in the carbon footprint declaration. They may be reported separately as additional information.

Carbon footprint performance classes

Carbon footprint performance classes will be established based on the market’s distribution of carbon footprint declarations. The classes will be ranked from A (best) to subsequent classes, with Category A representing the lowest lifecycle carbon footprint. The European Commission will determine the threshold and width for each class using a three-year dataset of declarations, considering the performance of battery categories, technological advancements and other technical factors.

Maximum carbon thresholds

The European Commission will establish maximum lifecycle carbon footprint thresholds for each battery category based on carbon footprint declarations, market data on battery performance classes and consideration of technical and scientific developments in the field.

Secondary legislation following the EU Batteries Regulation

The EU Batteries Regulation enables the creation of 32 Delegated Acts (DA) and 15 Implementing Acts (IA) to update the Regulation based on market developments and technical progress.

These acts will be published between 2024 and 2031, starting with electric vehicle batteries, followed by industrial batteries without external storage, light means of transport batteries, and finally, industrial batteries with external storage. The first delegated act for EV batteries has been released in draft format.

The Joint Research Centre (JRC) is providing technical support for developing secondary legislation on battery carbon footprint (CFB) under the EU Batteries Regulation (Regulation (EU) 2023/1542). This includes:

- Declaring CFB for rechargeable industrial batteries, light means of transport batteries and electric vehicle batteries

- Defining Carbon Footprint rules for industrial batteries (CFB-IND)

The JRC is building on previous work for electric vehicle batteries and the outcomes of stakeholder events in December 2023 and July 2024.

The EU Batteries Regulation requires a mix of company-specific and secondary data for carbon footprint calculation to obtain accurate results while limiting administrative burden.

- Company-specific data refers to primary data directly measured or collected from company facilities (primary data)

- Secondary data is sourced from third-party databases or other sources, including industry average data and proxy data

Current developments suggest that company-specific primary data is only necessary for the main product production (manufacturing) lifecycle stage, whereas secondary or average data may be used for other stages.

The Battery Pass consortium guidance recommends calculating battery carbon footprint using the Global Battery Alliance (GBA) GHG Rulebook and Battery Pass Rules, ensuring compliance with EU delegated act requirements. These documents build on existing standards, cover the battery lifecycle from cradle to grave, and provide guidance on collecting and using company-specific data.

This approach will provide a robust data basis for measuring and optimising real-world carbon footprints along the value chain.

Company-specific data reporting

According to the draft EV delegated Regulation, battery manufacturers must ensure that suppliers provide company-specific data in one of three ways:

- Complete LCI: Suppliers provide a comprehensive Lifecycle Inventory (LCI) of the process, including:

- Elementary flows

- Energy consumption

- Input materials

- Recycled content

- Information for carbon footprint study/documentation verification

- Company-Specific Dataset: Suppliers provide a dataset specific to their company.

- Third-Party Data Management: Suppliers provide LCI data – including elementary flows, energy consumption, input materials, recycled content and information required for carbon footprint study and verification – to a third-party data company that combines the inputs from various suppliers and provides the manufacturer with a company-specific dataset for different processes.

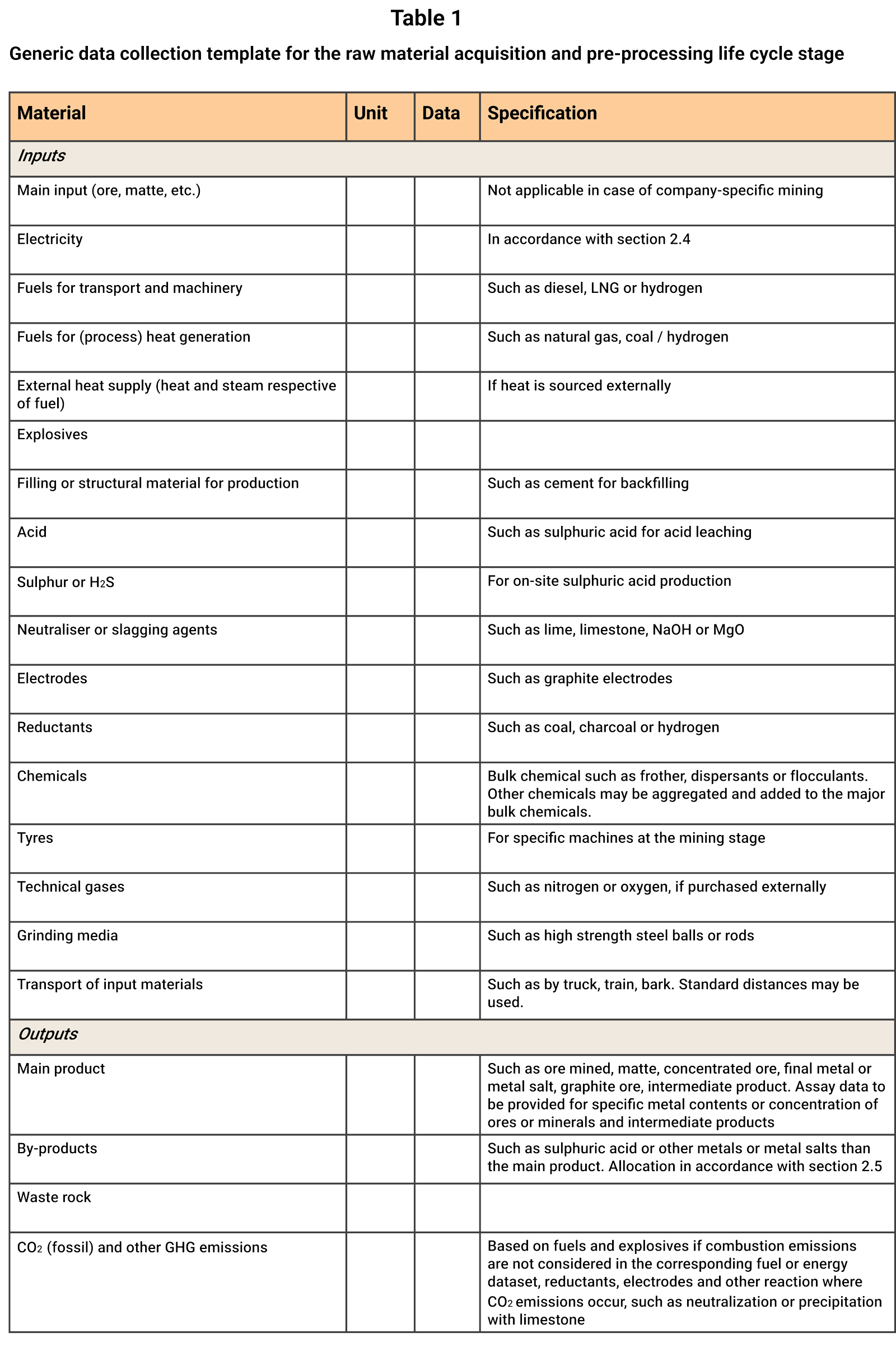

To create a company-specific dataset, the following data must be collected:

Inputs:

- Material inputs (minerals, metals, semi-finished materials, chemical feedstocks) with specific concentration data

- Energy consumption (direct and indirect) in the processing plant

- Transport distances and means of transport

- Any elementary flows (materials or energy entering the system without previous human transformation)

Outputs:

- Material outputs (including wastewater)

- Any elementary flows (materials or energy leaving the system without subsequent human transformation)

Data averaging:

Company-specific data is to be averaged over a one-year period. However, if a process is less than a year old, the data may be averaged over a shorter period. In exceptional cases, a different averaging period may be used if it is justified in the carbon footprint study. Data may be collected for each process or subprocess stage separately or for the final production as a whole.

How to use Metallurgical Intelligence® to track company and product-specific data

While company-specific data is not yet mandatory across all stages of the battery’s lifecycle for the calculation of a carbon footprint declaration, Metallurgical Systems strongly recommends that all battery suppliers and manufacturers collect, track and analyse their company-specific data to be ready for current and future requirements.

Depending on a manufacturer’s specific situation, the Regulations can require carbon footprint calculations and declarations using primary data specific to each battery product, model and manufacturing plant. For example, secondary data isn’t sufficient for the main battery production lifecycle stage.

This means relying on general data such as procurement spending, supplier surveys and assumptions and averaged data, as well as using spreadsheets and manual reporting, will not meet compliance and disclosure requirements.

Only digital data collection and analysis tools will enable the delivery of the traceable and auditable product-level reports required to produce battery carbon footprint declarations needed by regulators and stakeholders.

Product-level calculations and reporting

A unique feature of Metallurgical System’s Sustainability software is that it enables mining and minerals operations to calculate their carbon footprint right down to a product level.

Using automated Product Lifecycle Assessment (LCA), Lifecycle Inventories (LCI) and Product Carbon Footprinting (PCF) methods, the solution calculates emissions by quantifying the energy, materials and waste in complex production processes as well as transport costs and much more.

This provides a complete data set of cradle-to-gate and cradle-to-grave impacts, from extraction of raw materials to processing, production and distribution. Using comprehensive in-built calculations, customised reports can be delivered from an enterprise-wide view down to defined geographic locations, specific sites, boundary, category and product levels.

Track detailed data across the production process by individual product

Equipping organisations to meet evolving sustainability reporting obligations – including EU Batteries Regulation – Metallurgical Intelligence® enables calculation of activity data across the production process for each country, site, site boundary, scope, reporting category (such as fuels, reagents, waste, energy and water) and data type by individual product.

Examples of activity data that is derived from validated measured data and calculated data at a product level include:

- Quantity of fuel used

- Kilowatt hours of electricity used

- Production output

- Distance travelled

- Input consumption

- Waste produced to landfill and waste composition

- Water and consumption

- Volume of gases emitted and gas composition

How Metallurgical Intelligence® collects, tracks and reports company-specific data

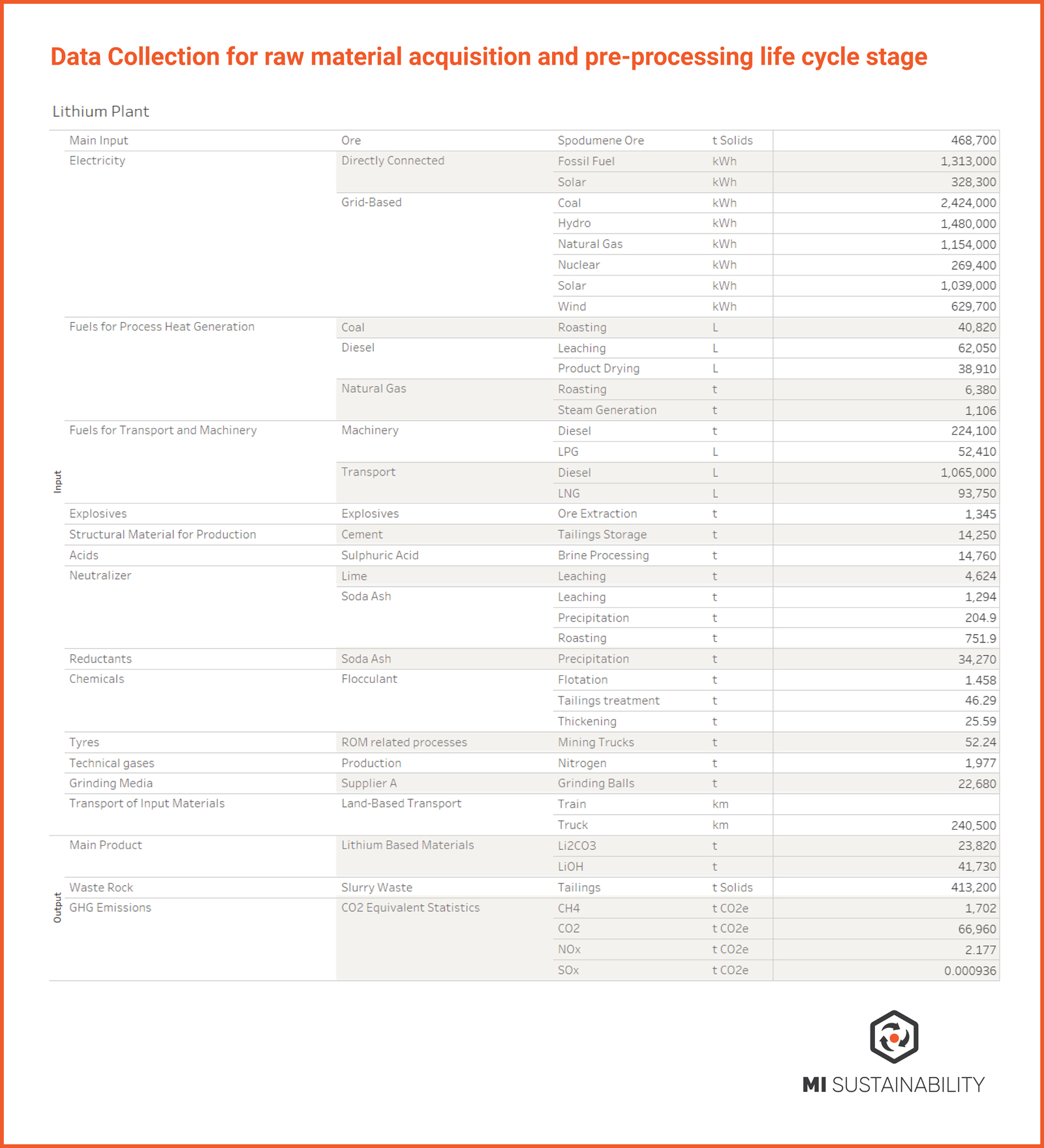

Below is a template provided in the draft EV supplementing Regulation that may be used for the data collection for each process stage in the raw material acquisition and pre-processing lifecycle stage. This data is to be provided for each material at a specific production plant.

The table below shows an example of how Metallurgical Intelligence® collects, processes and validates the company-specific granular activity data that sits behind the aggregated data at a per input material level per production plant. The table demonstrates how this data can be used to calculate the data requirements for one of the battery lifecycle stages, raw material acquisition and pre-processing.

Using a lithium plant as an example of the raw material supplied to a battery manufacturer, we have aligned the data captured and calculated by Metallurgical Intelligence® from the production process to the reporting format required by the Batteries Regulation.

This case study outlines how we helped a leading scientific organisation to cut emissions and waste by measuring an accurate reporting baseline and to set targets and test scenarios using steady-state simulation.

Explore how the mining, minerals and resource sector can meet evolving sustainability disclosure and reporting standards with an intelligent data-driven sustainability reporting platform.

Take control of your EU Batteries Regulation compliance

Complementing our proven Metallurgical Intelligence® reporting and analysis software, for over 20 years the team at Metallurgical Systems has been providing a range of mining and metallurgical consulting services to help minerals processing plants optimise their operational processes using a combination of industry expertise and intelligent technology.

To learn how Metallurgical Intelligence® can help create transparent, consistent and complete sustainability reports that comply with EU batteries compliance regulations and other emerging and evolving frameworks, contact our expert team on +61 2 7229 5646 or info@metallurgicalsystems.com

About the authors

This article has been collaboratively authored by the team at Metallurgical Systems, and fact-checked and authorised by Managing Director and industry specialist John Vagenas.